How to Select the Right Circular Saw Blade for Any Project

Choosing the right circular saw blade is crucial for the success of any cutting project. The right blade can make a significant difference in the quality of your cuts, ensuring clean and precise results instead of rough and splintered edges that waste time and materials.

Choosing the right circular saw blade is crucial for the success of any cutting project. The right blade can make a significant difference in the quality of your cuts, ensuring clean and precise results instead of rough and splintered edges that waste time and materials.

Why Professional Craftsmen Understand Circular Saw Blades

Professional craftsmen understand that circular saw blades are not one-size-fits-all tools. Each type of blade serves a specific purpose, whether it's ripping through hardwoods or creating smooth finishes in delicate materials. By using the right blade for each task, professionals can:

- Improve project efficiency

- Extend the lifespan of their tools

- Achieve superior results

At Prime Source, we recognize the importance of having high-quality tools to ensure your success. With over ten years of experience in providing various options for circular saw blades and offering expert advice, we have assisted numerous professionals and DIY enthusiasts in optimizing their cutting operations. Our wide range of circular saw blades designed for cutting metal and other materials demonstrates our dedication to meeting different project requirements.

What This Guide Covers

In this guide, we will discuss the key factors you should consider when selecting circular saw blades, including:

- Blade materials and construction

- Tooth count and configuration

- Applications for specific materials

- Size and compatibility needs

- Safety considerations

Let our knowledge help you find the ideal blade for your upcoming project.

Understanding Circular Saw Blades

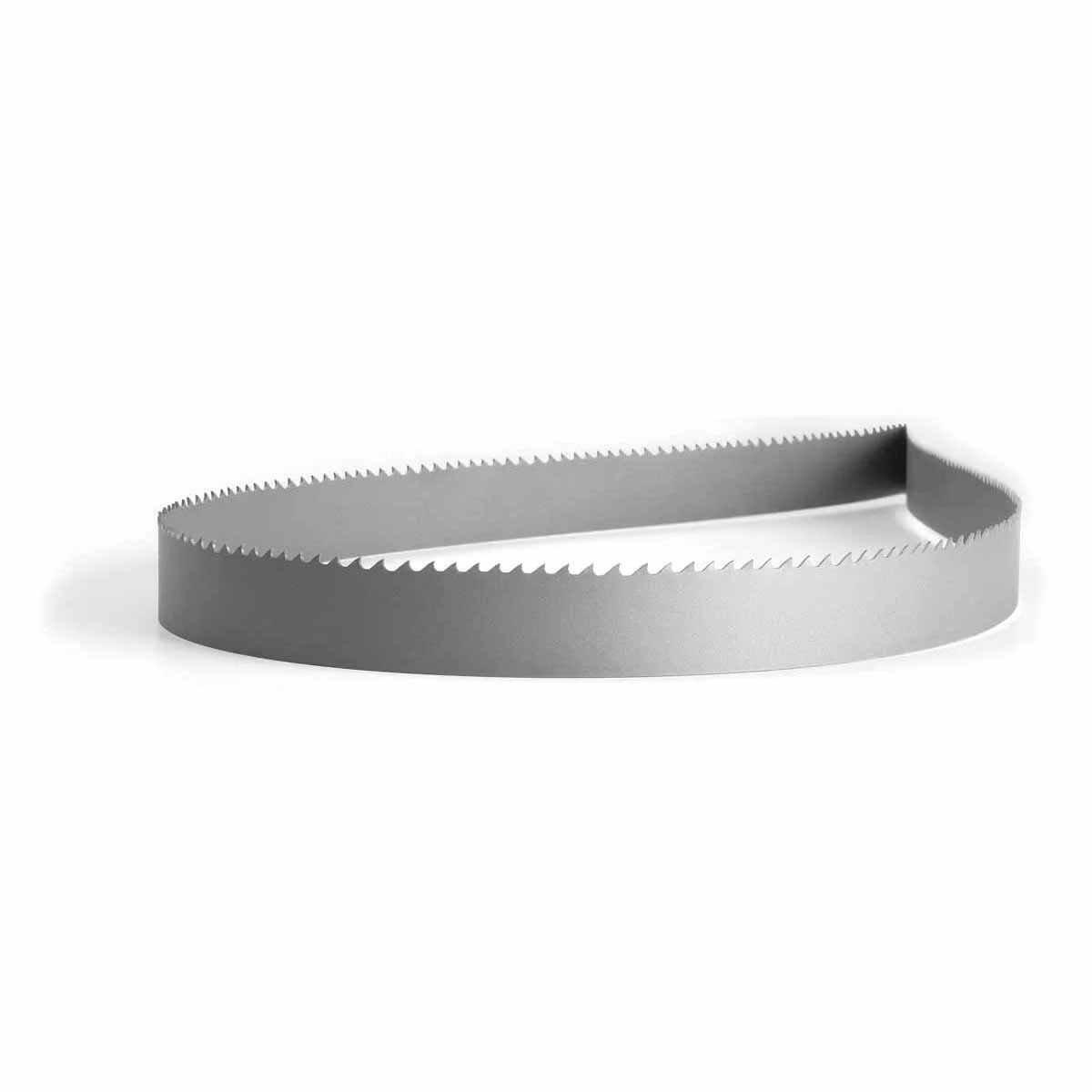

There are various types of circular saw blades designed for specific cutting needs. The effectiveness of a rotating saw blade depends mainly on its construction material and design features. In this section, we will explore the main types of circular saw blades available in the market today.

1. Blade Types

Carbide-Tipped Blades

- Premium choice for hardwood cutting

- Features tungsten carbide teeth welded to steel bodies

- Maintains sharpness up to 20 times longer than steel blades

- Ideal for precision cuts in oak, maple, and exotic hardwoods

- Resists wear in high-temperature cutting conditions

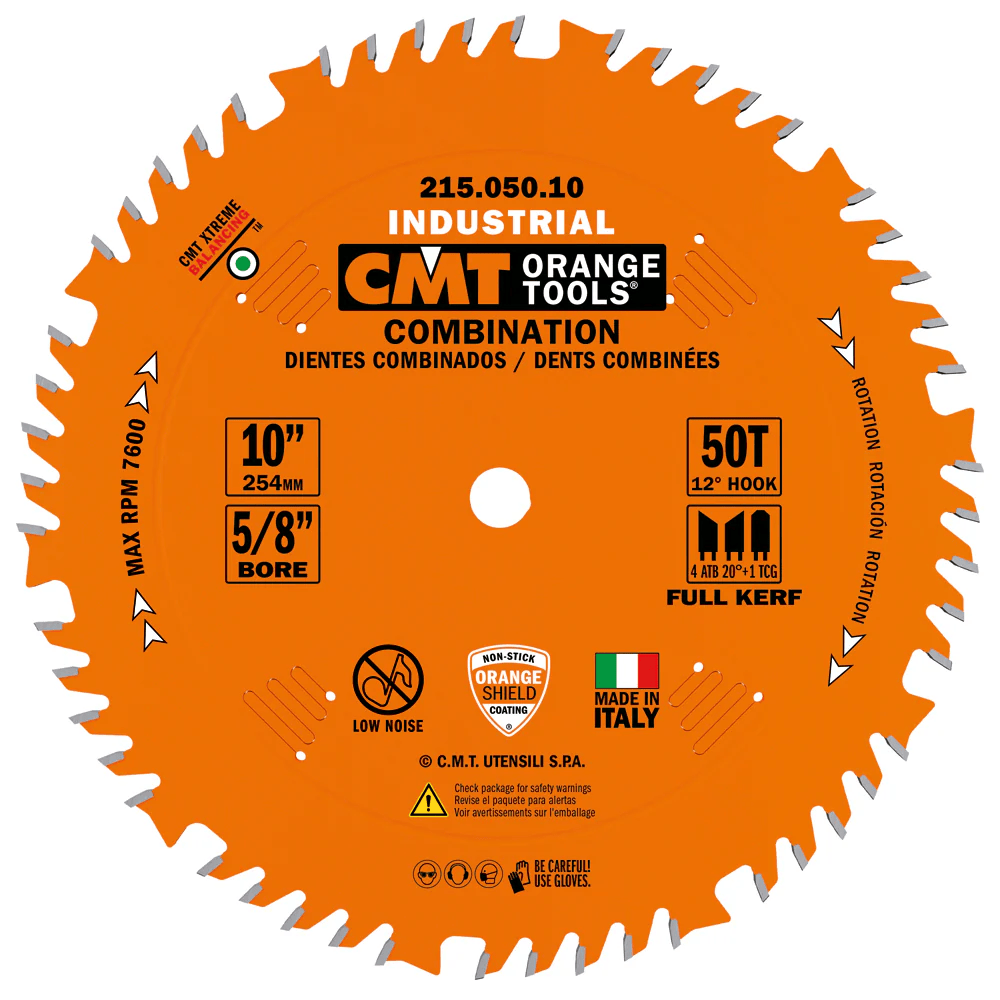

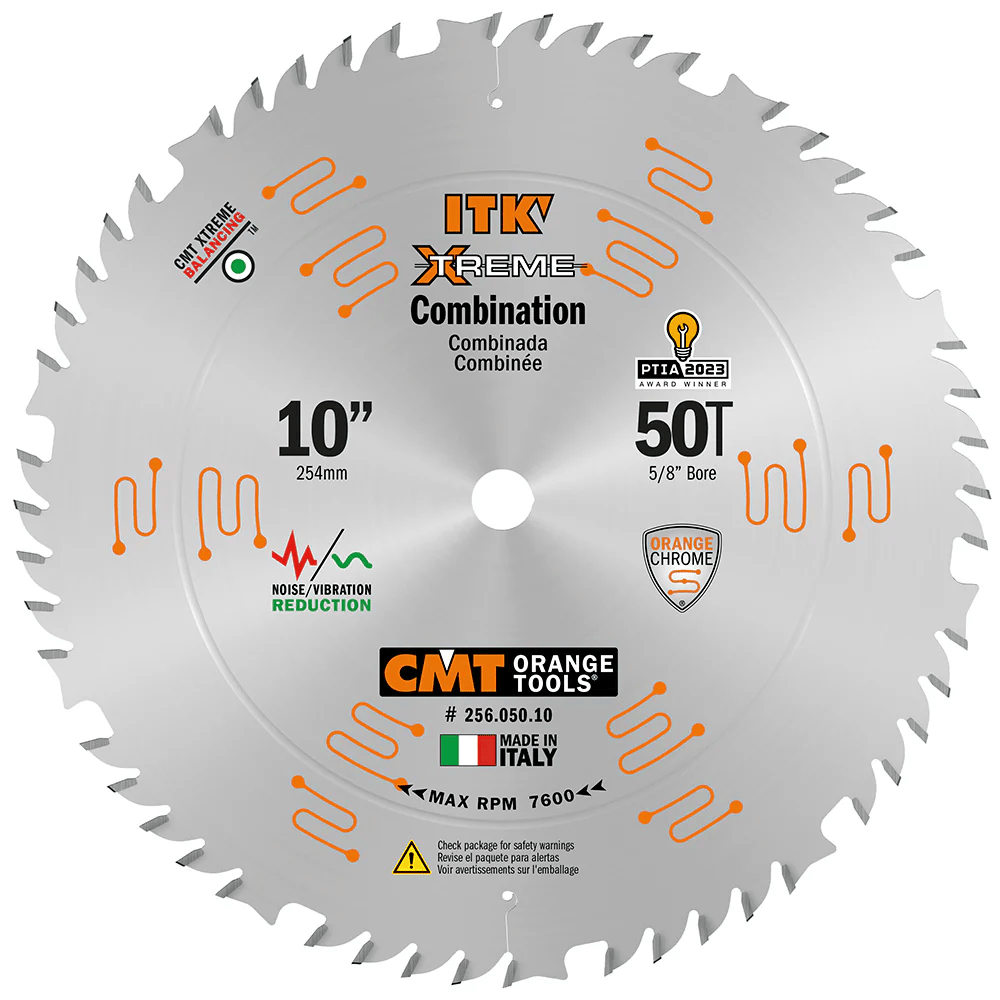

For example, circular saw blade such as the CMT 256.050.10 are a great option with excellent resistance to corrosion and mechanical wear.

High-Speed Steel (HSS) Blades

- Cost-effective option for occasional use

- Perfect for softwood and light-duty applications

- Delivers clean cuts at higher speeds

- Requires more frequent sharpening

- Suitable for DIY projects and basic woodworking tasks

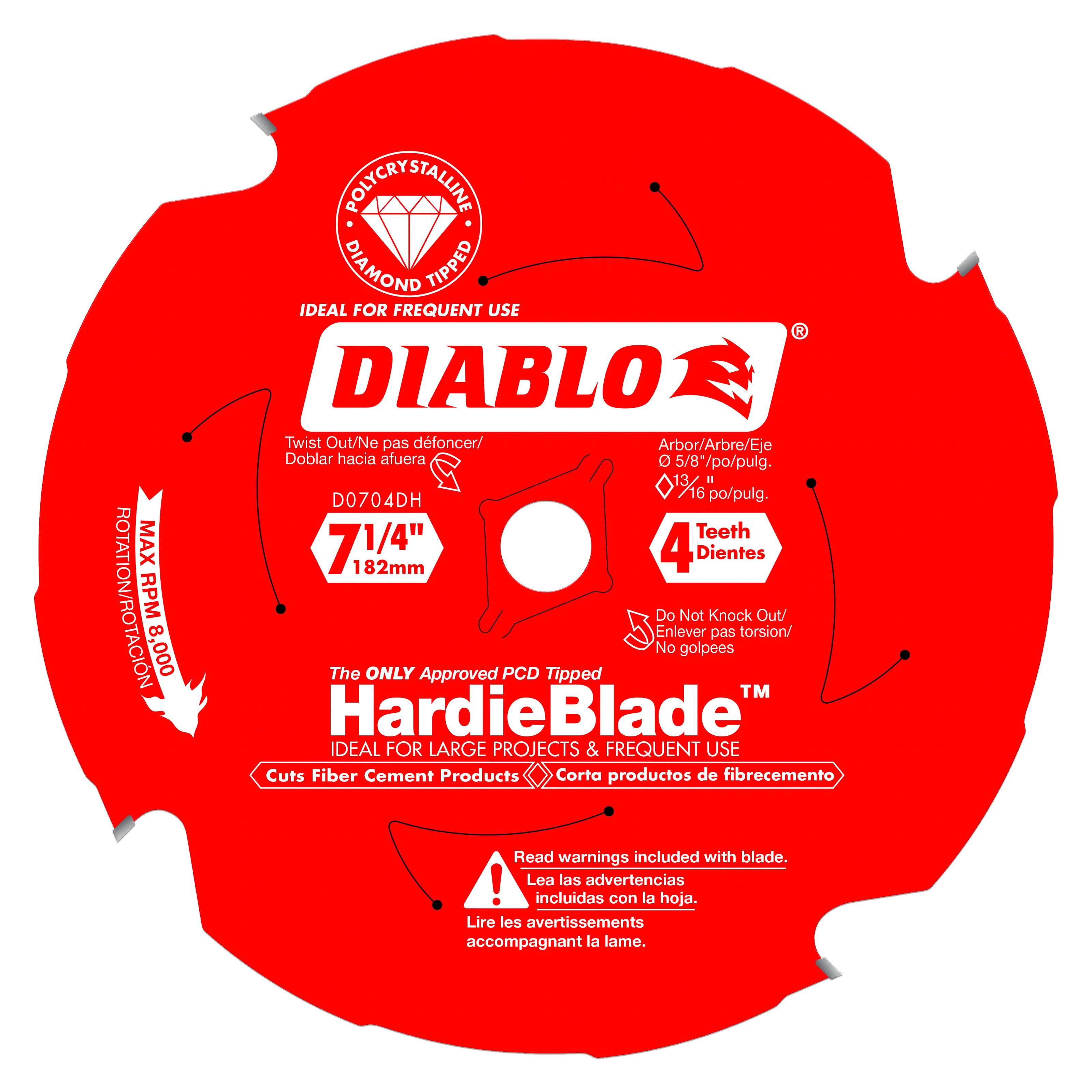

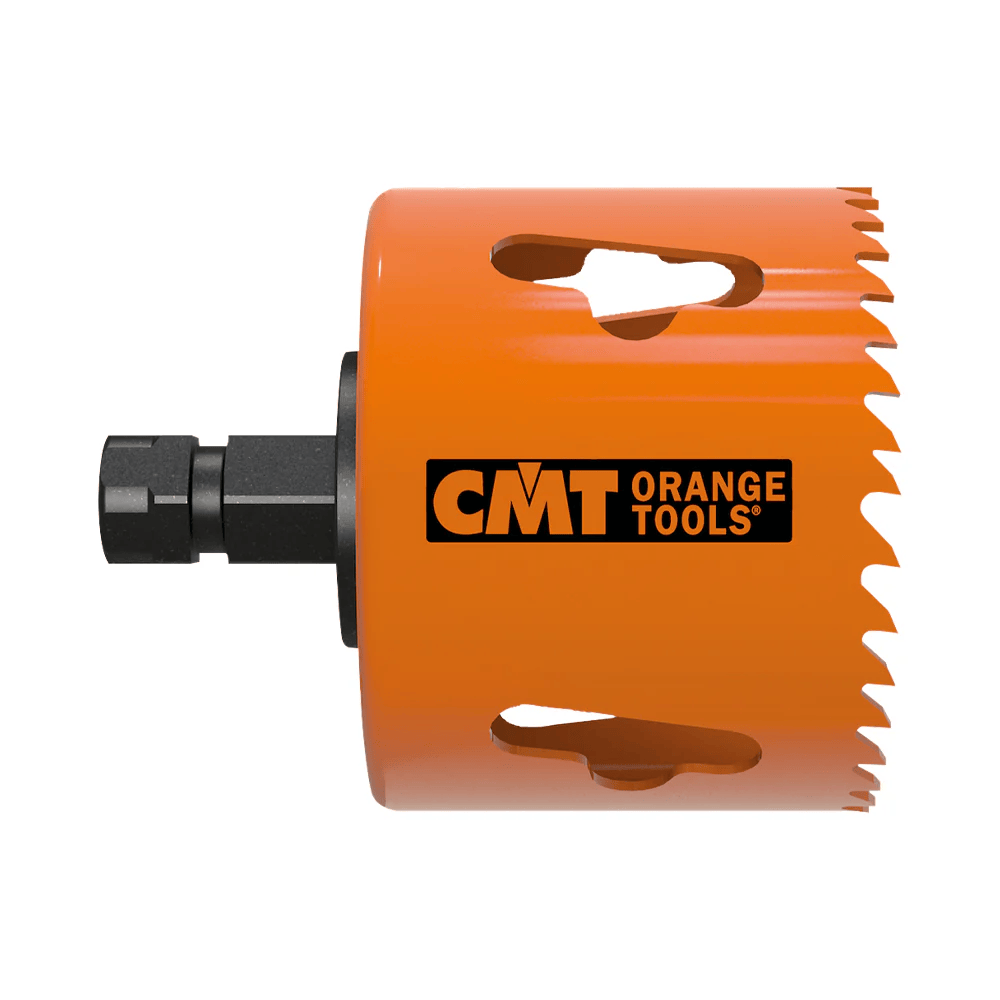

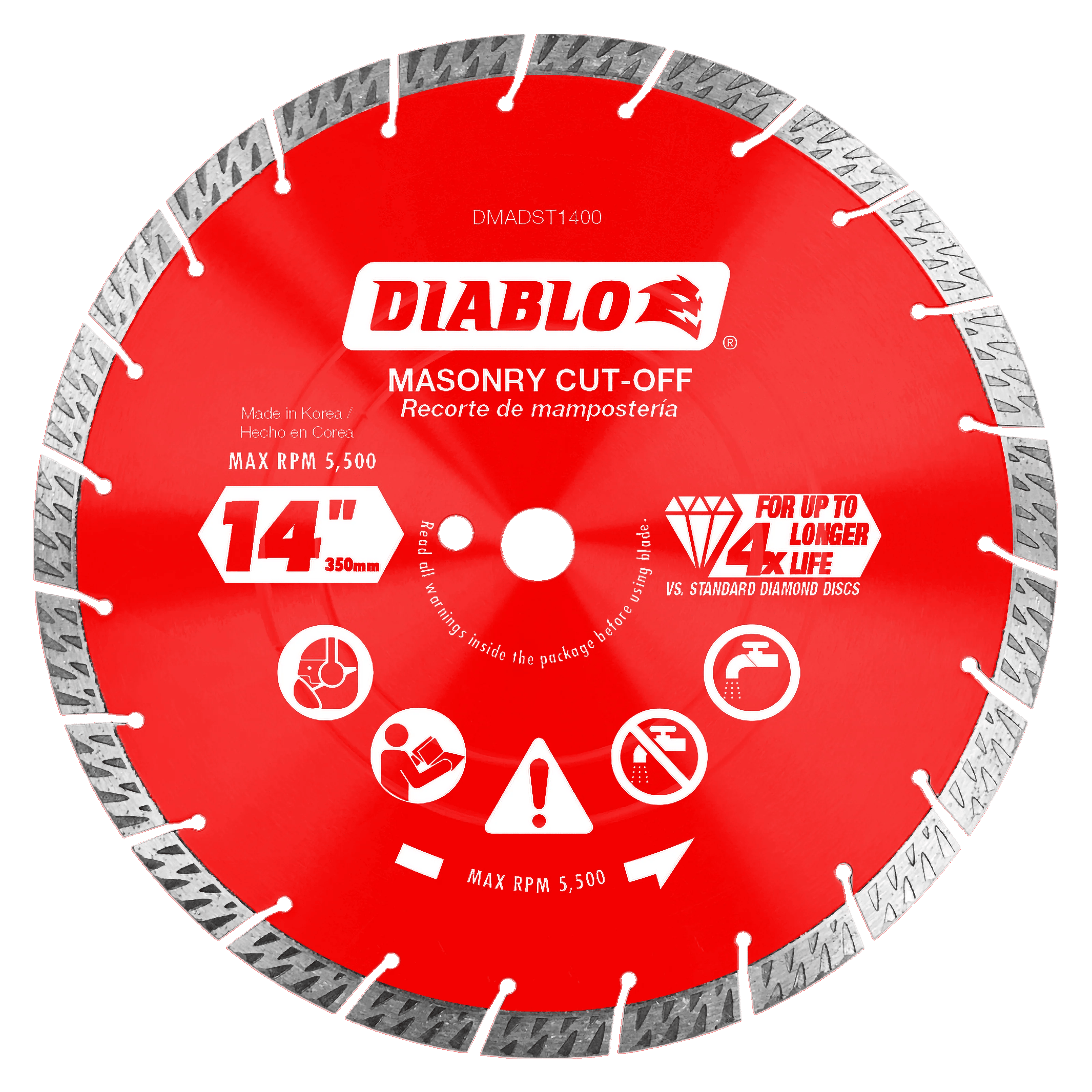

Diamond Blades

- Specialized saw circular blade for masonry work

- Cuts through concrete, stone, and tile with precision

- Features industrial-grade diamonds bonded to blade edges

- Provides extended life in abrasive materials

- Requires water cooling for optimal performance

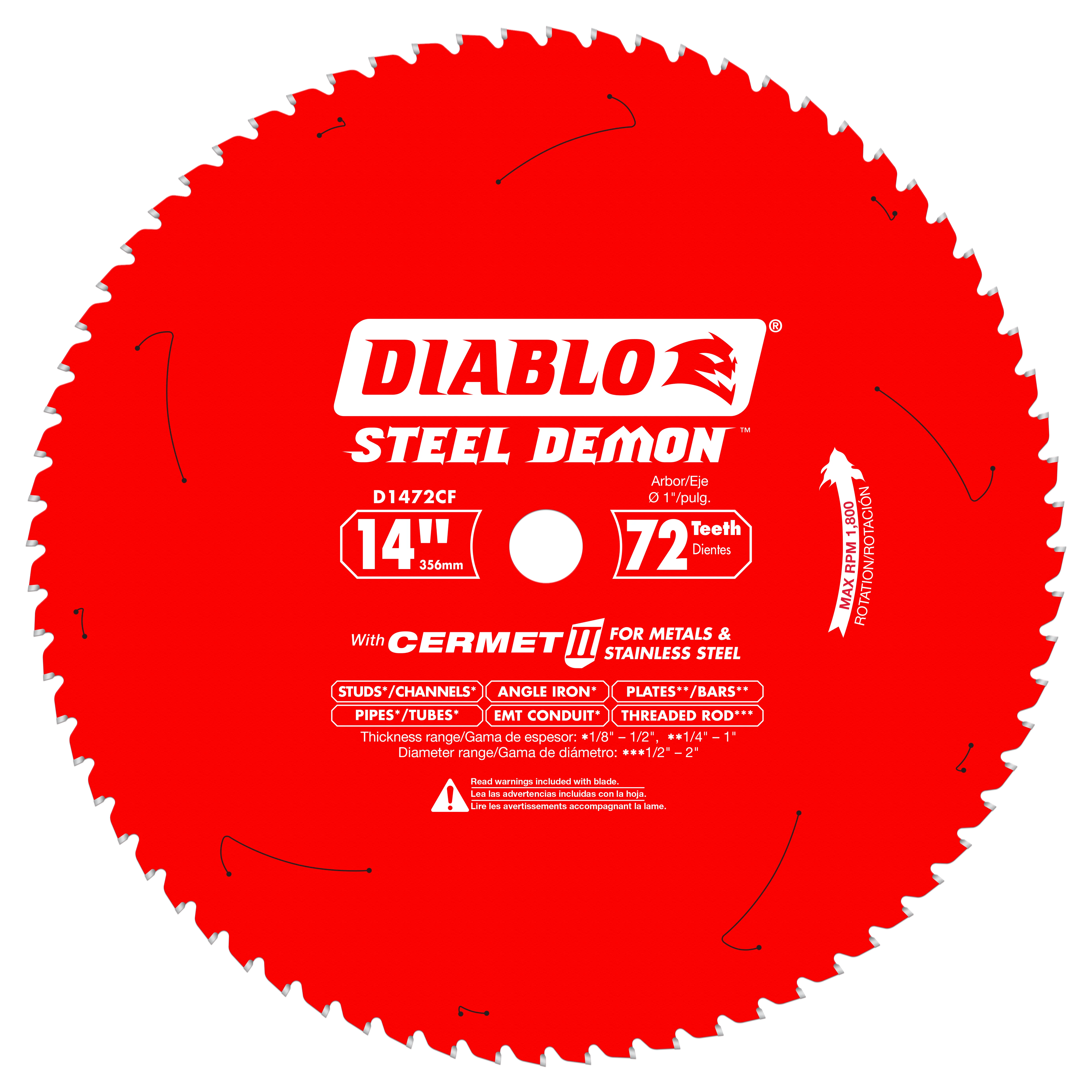

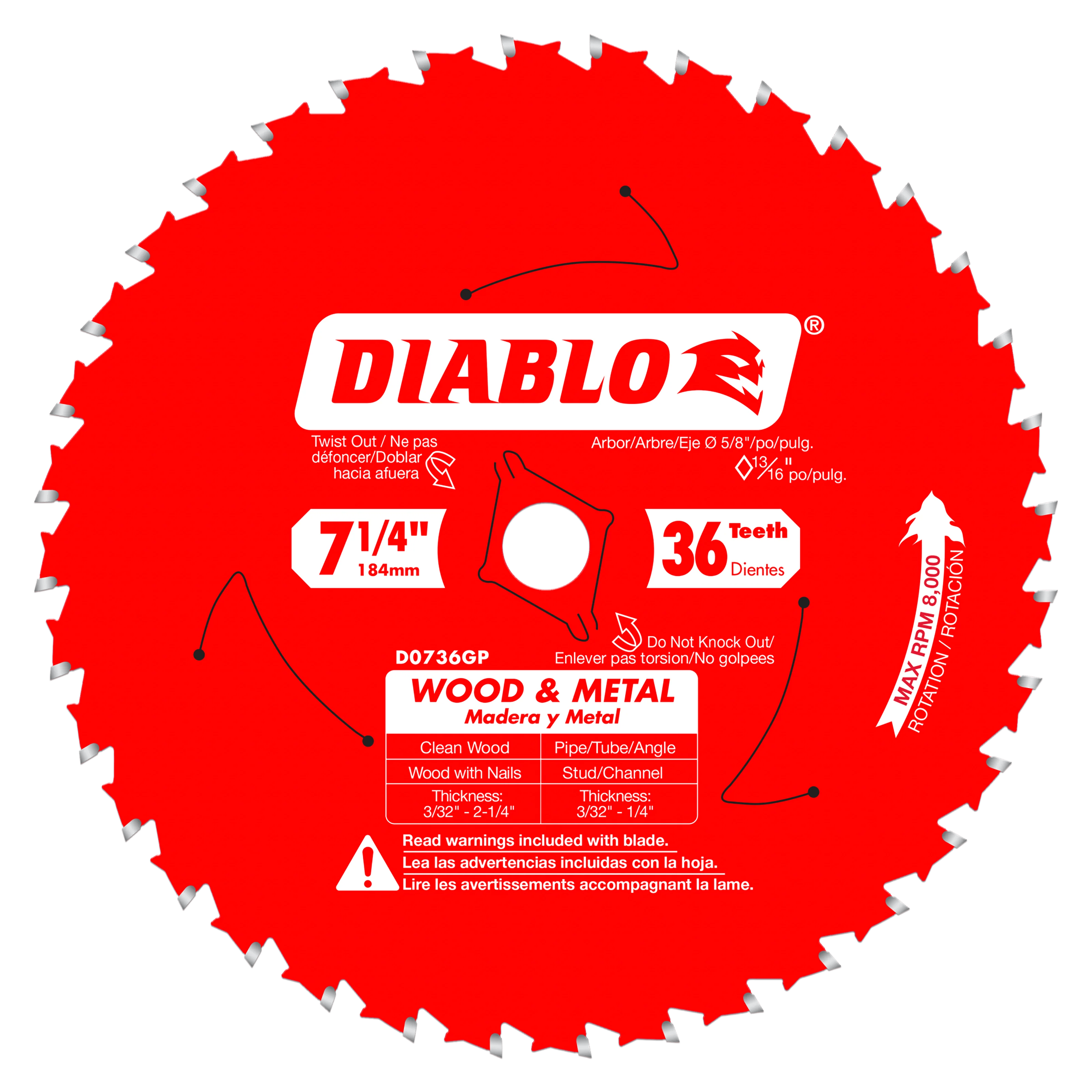

The circular saw for cutting metal requires specific blade configurations. Metal-cutting blades typically feature:

- Fine tooth patterns

- Special coating for heat resistance

- Reinforced cores to prevent warping

- Specific tooth geometries for clean cuts

Each blade type serves distinct purposes in construction and woodworking:

- Carbide-tipped blades excel in professional settings where durability meets precision.

- HSS blades offer accessibility for hobbyists and occasional users.

- Diamond-tipped options handle the toughest materials with remarkable efficiency.

The selection of a circular saw blade directly impacts:

- Cut quality

- Project completion time

- Tool longevity

- Material waste reduction

- Safety during operation

Professional users often maintain multiple blade types to handle various materials and cutting requirements. This versatility ensures optimal performance across different applications while maximizing efficiency and cut quality.

Additionally, specialized tools like Diablo D1296N 12" x 96-Teeth Saw Blade can further enhance your metalworking capabilities by providing precise cutting results on aluminum.

Understanding the different types of circular saw blades and their applications can significantly improve your efficiency and effectiveness in both professional and DIY projects.

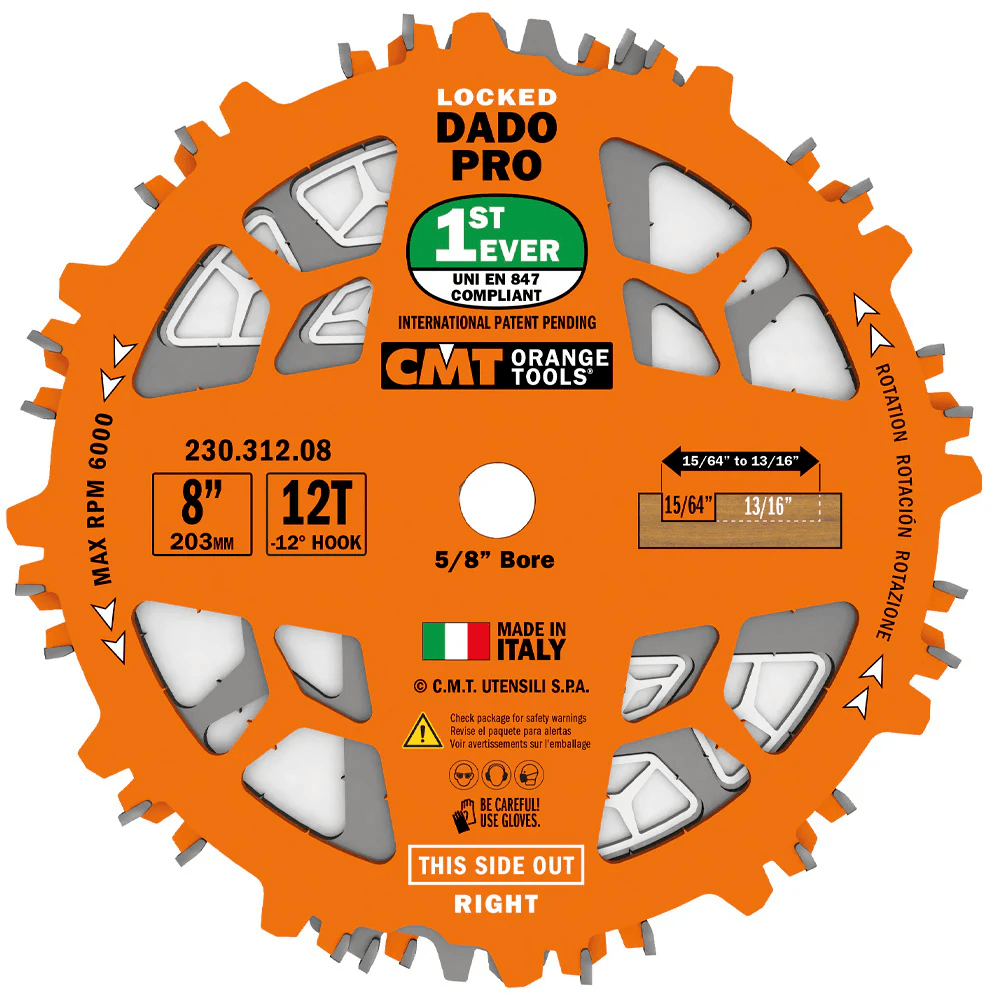

2. Material-Specific Blades

Different materials require specific circular saw blades for the best cutting results. A saw blade made for wood won't cut metal cleanly, just as a saw made for cutting metal might damage delicate laminates.

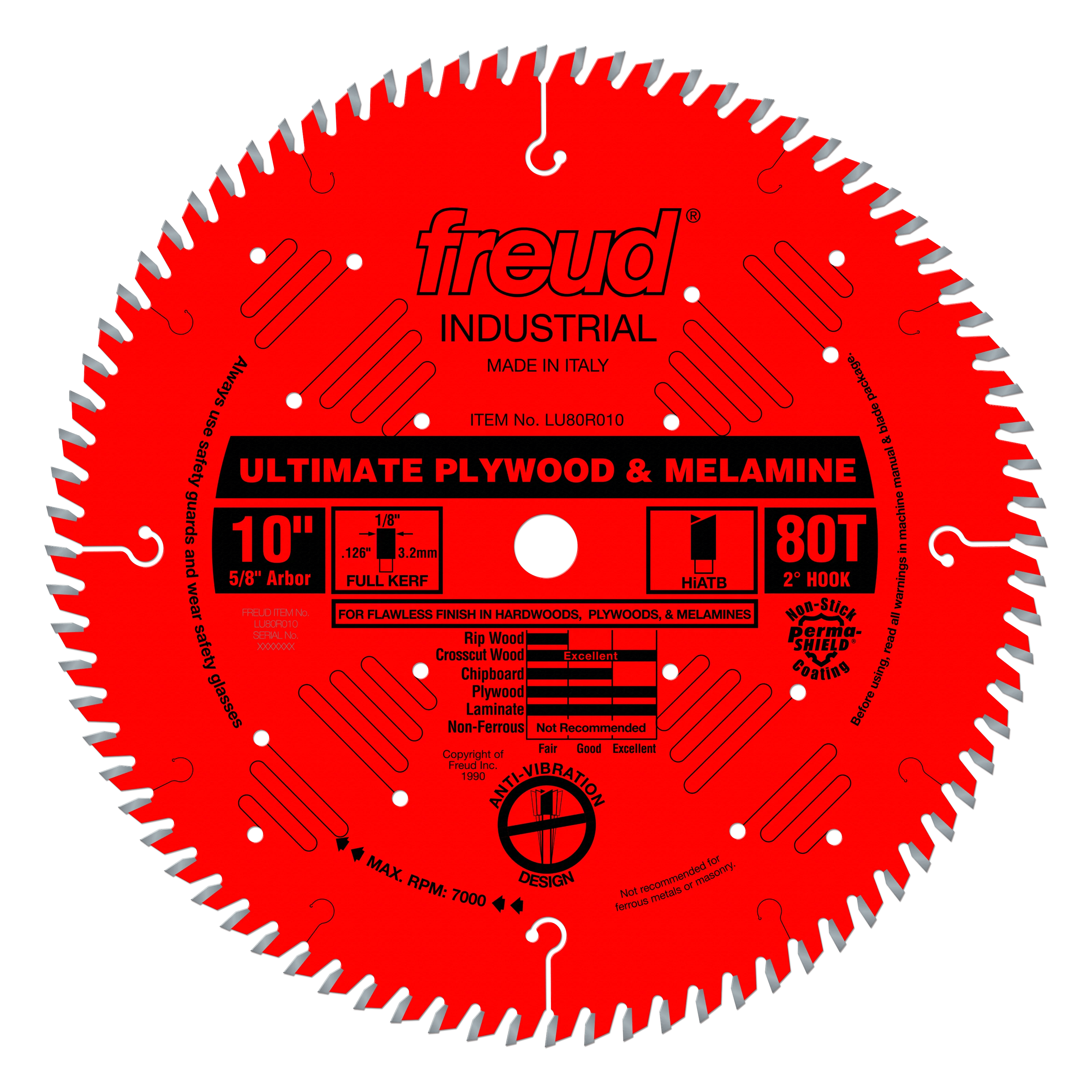

Laminate and Melamine

- Fine-tooth blades (60-80 TPI)

- Triple-chip grind design

- Prevents chipping and splintering

- Delivers clean, splinter-free edges

- CMT 283.680.10 is ideal for single and double sided laminate trimming.

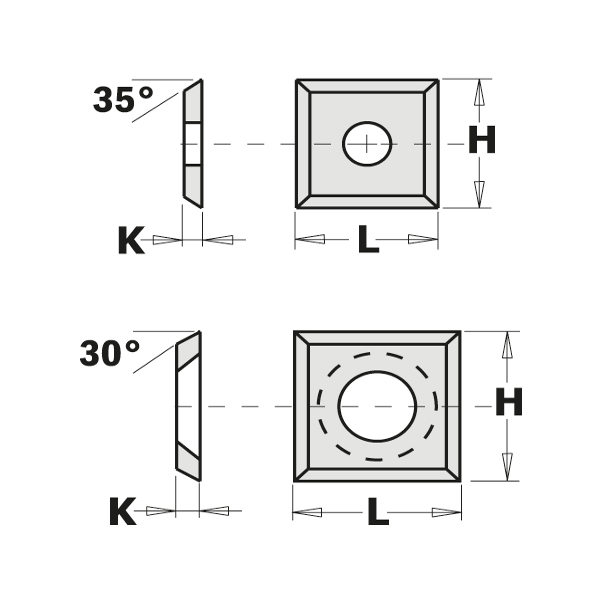

Aluminum and Non-Ferrous Metals

- Negative hook angle

- Special tooth geometry

- Reduces heat buildup

- Prevents material binding

- For heavy-duty cutting on aluminum, brass, copper, PVC and other non-ferrous metals, the D12120N 12" 120-Tooth Thin Aluminum Cutting Circular Saw Blade is excellent.

Plywood and Veneers

- High TPI count (80-100)

- Alternating top bevel teeth

- Minimizes tear-out on both sides

- Ideal for delicate face veneers

Masonry and Concrete

- Segmented diamond-rim design

- Cooling channels

- Reinforced core

- Requires wet cutting for dust control

The choice of circular saw blade affects both the quality of the cut and the lifespan of the tool. Specialized blades usually need to be replaced after 12 to 24 hours of continuous use, depending on how dense the material is and how often you cut. Hard materials like concrete wear down the blade faster, so you'll need to change it more often compared to softer materials like plywood.

Choosing the Right Cut Type and Teeth Per Inch (TPI) Considerations

The effectiveness of your circular saw blade depends heavily on two critical factors: cut type and teeth configuration. A rotating saw blade's performance varies significantly based on these specifications.

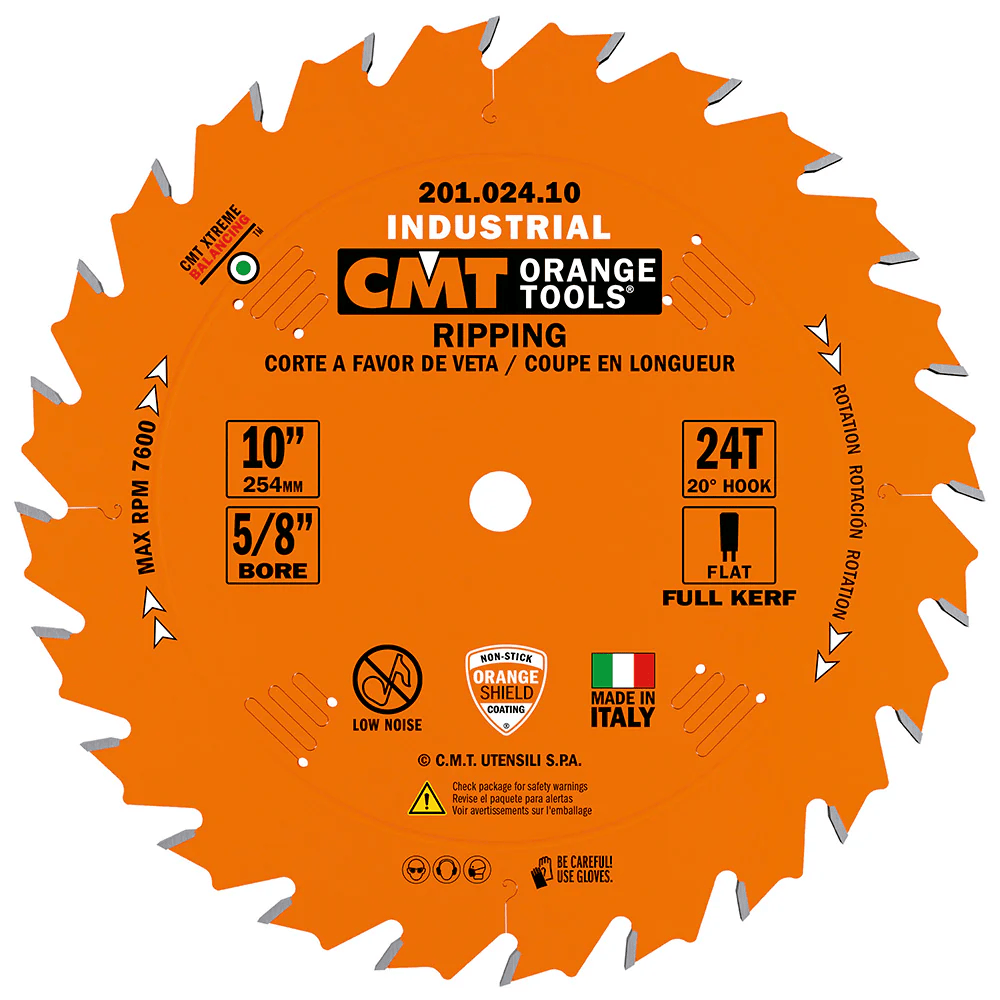

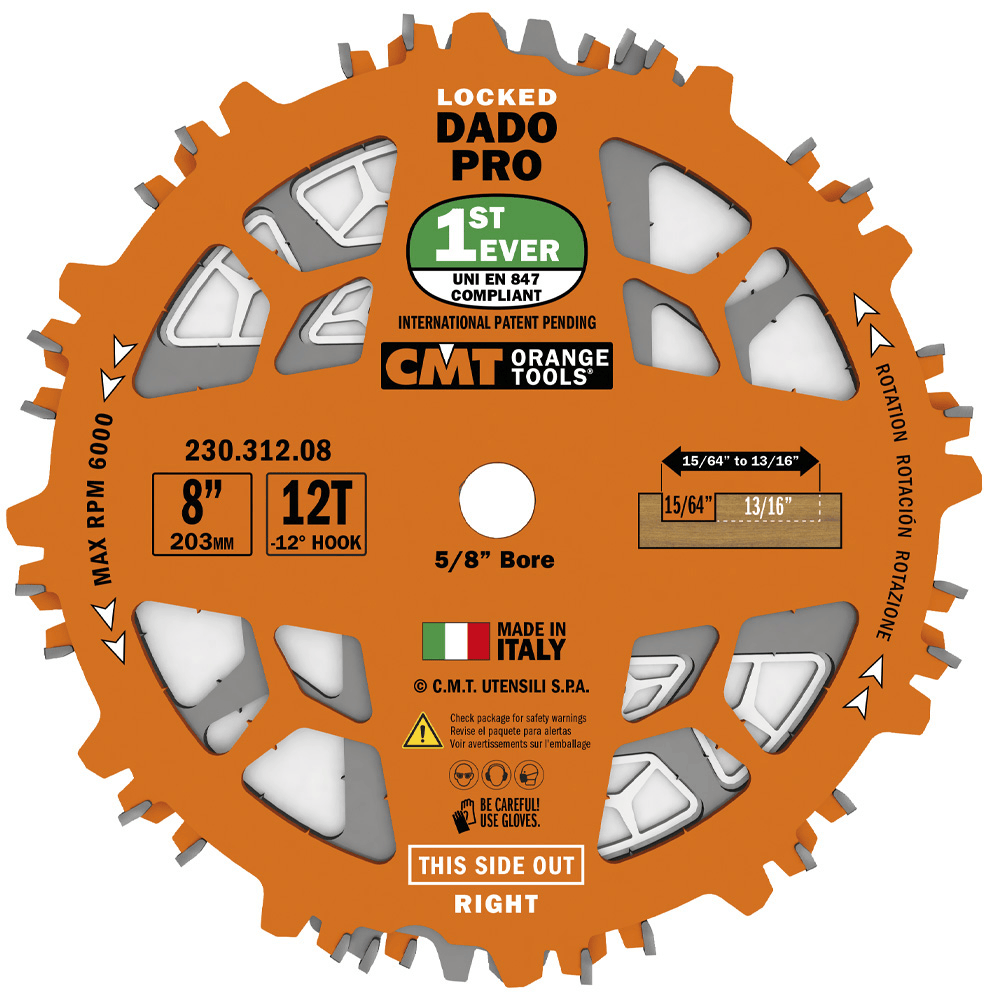

1. Rip-Cut Blades

Designed for cutting parallel to wood grain, rip-cut blades feature 24-30 teeth with deep gullets between them. These circular saw blades excel at removing material quickly while maintaining straight cuts. The aggressive tooth design efficiently clears sawdust, preventing binding and ensuring smooth operation.

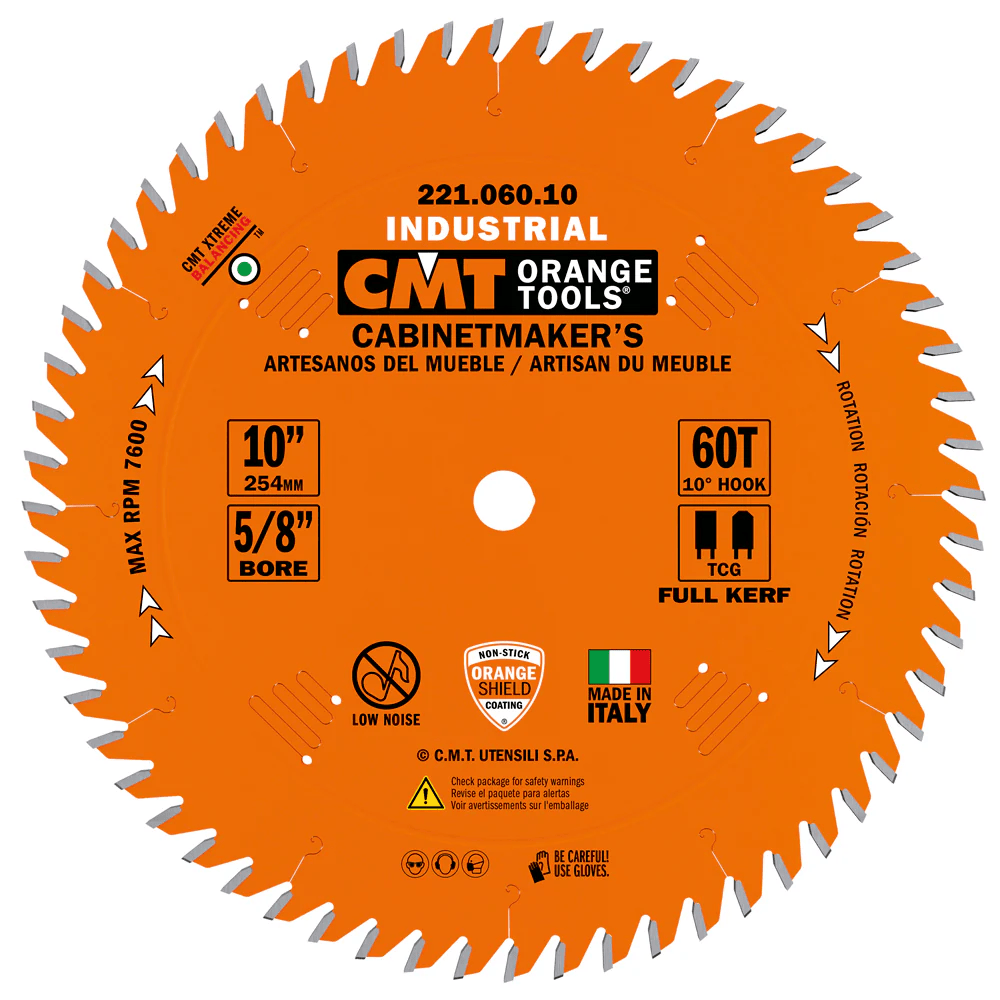

2. Crosscut Blades

These specialized blades contain 60-80 teeth positioned to slice cleanly across wood grain. The saw circular blade configuration minimizes tear-out and splintering, producing precise, clean edges. Crosscut blades prove invaluable for trim work and finish carpentry where appearance matters.

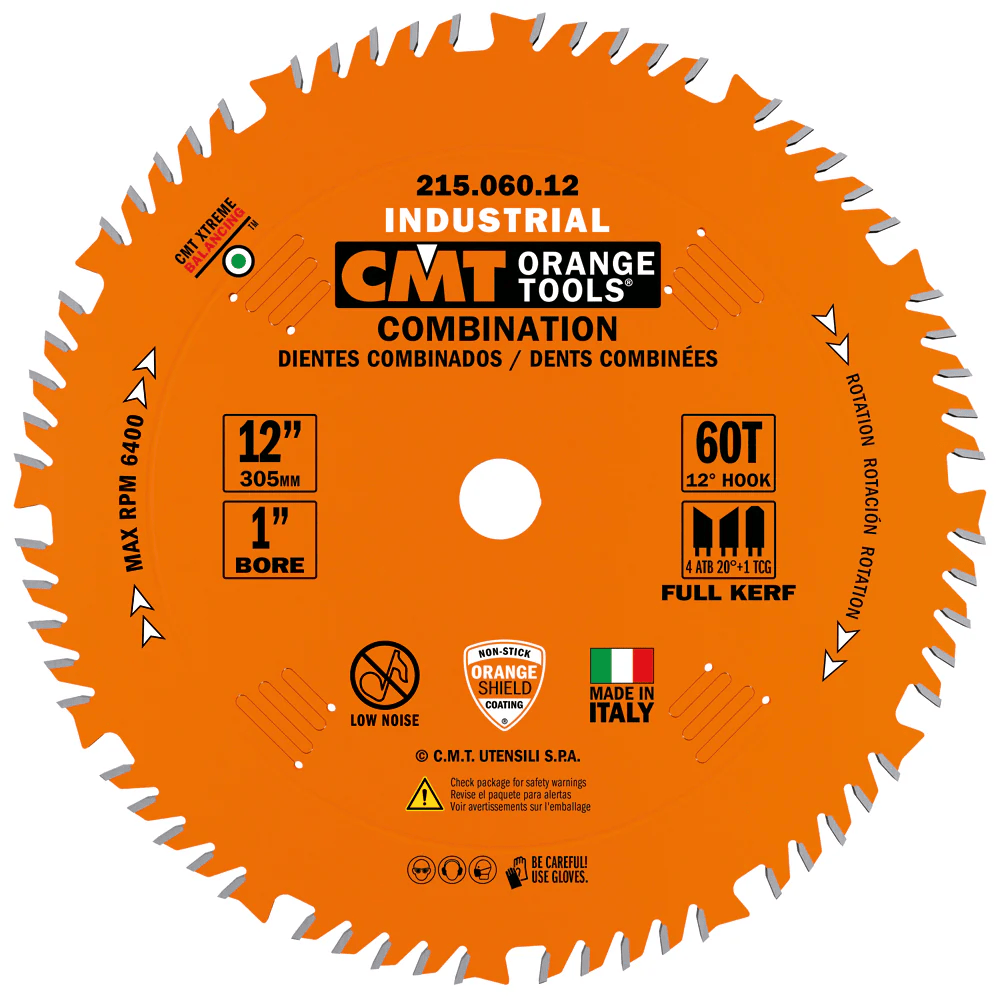

3. Combination Blades

A versatile option, combination blades merge the benefits of both rip and crosscut designs. With 40-50 teeth arranged in groups, these circular saws offer acceptable performance for both cutting directions. While not matching specialized blades' excellence in specific tasks, they provide practical flexibility for varied projects.

4. TPI Impact on Performance

Cut Quality vs. Speed Trade-off:

- Low TPI (14-24): Fast cutting, rougher finish

- Medium TPI (40-50): Balanced performance

- High TPI (60-120): Slower cutting, smoother finish

The relationship between tooth count and cutting speed creates distinct advantages for different applications. Lower tooth counts remove material quickly but leave rougher surfaces. Higher tooth counts produce finer cuts at reduced speeds, ideal for visible surfaces and precision work.

Blade Selection Tips:

- Choose low TPI for construction lumber and rough cuts

- Select medium TPI for general-purpose work

- Opt for high TPI when finish quality is paramount

- Consider material thickness - thicker materials benefit from fewer teeth

For instance, if you're working on a project that involves creating dovetail joints, it's advisable to use a low TPI blade to ensure quick material removal while maintaining the necessary precision for these intricate cuts.

Alternatively, if your project requires a plunge cut through various materials such as wood or metal, a medium TPI blade would provide the balanced performance needed for such tasks.

Key Blade Features to Evaluate and Ensuring Compatibility with Your Saw

The Importance of Tooth Hook Angle

The tooth hook angle of a rotating saw blade plays a vital role in cutting performance. A positive hook angle (typically 10-20 degrees) creates an aggressive cut ideal for ripping operations, while a negative hook angle provides controlled cuts essential for delicate materials. Selecting the appropriate hook angle helps minimize tear-out - those unsightly splinters and rough edges that can mar your workpiece.

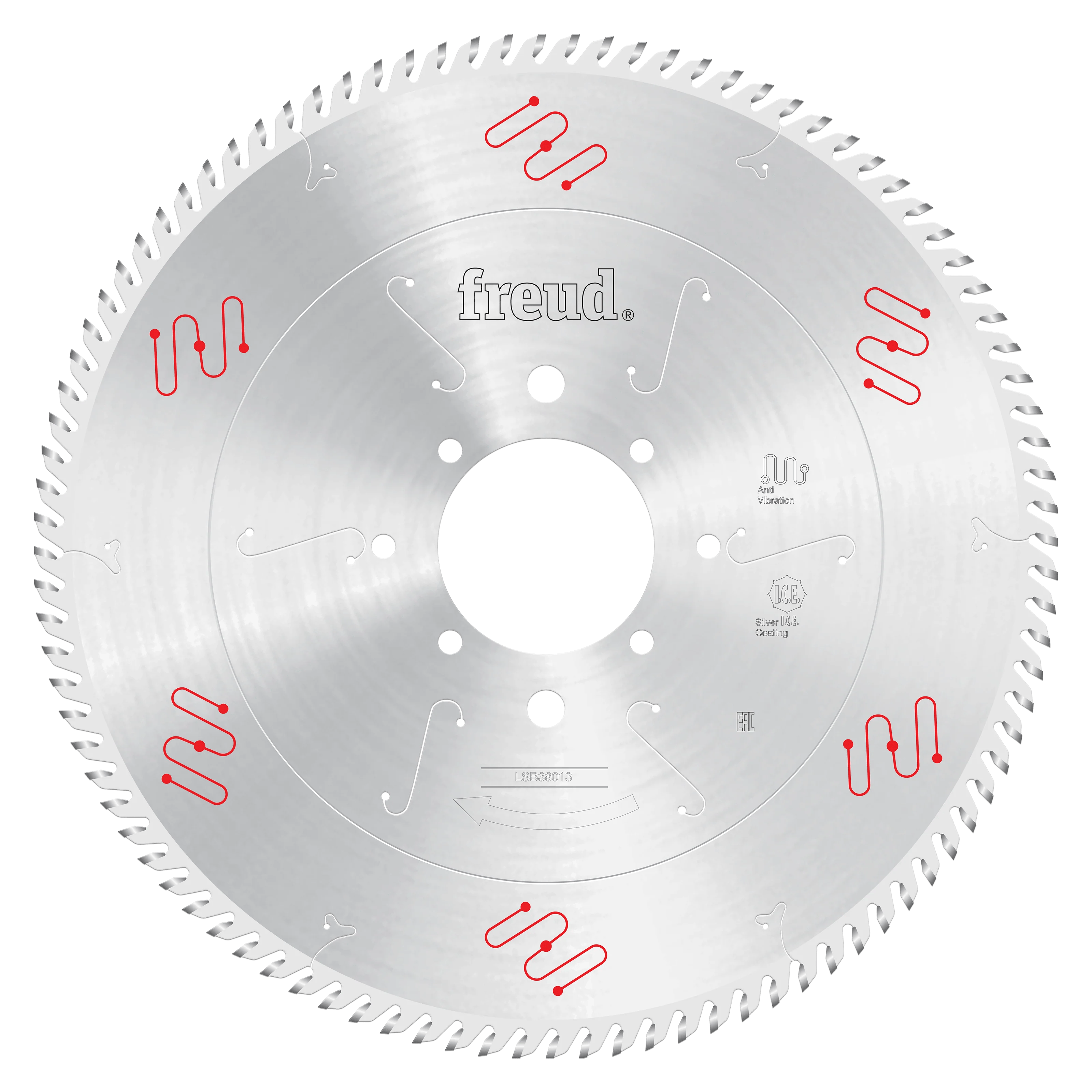

Understanding Expansion Slots

Expansion slots are crucial design elements in circular saw blades. These laser-cut channels allow the blade to expand and contract as it heats up during operation. Without these slots, the saw circular blade could warp under heat stress, leading to uneven cuts and potential safety hazards. Premium blades feature strategically placed expansion slots that maintain blade stability while reducing noise during operation.

The Role of Coatings in Blade Performance

Modern circular saw blades often come with specialized coatings that enhance their performance. Non-stick coatings reduce pitch build-up and friction, allowing the blade to run cooler and extend its life. Anti-corrosion coatings protect the blade from rust and environmental damage, particularly important for circular saw blades used in humid conditions or on treated lumber.

Common Blade Sizes and Applications

Knowing the common sizes and their respective applications can help you choose the right blade for your needs:

- 7-1/4": Standard size for portable circular saws, perfect for general construction and DIY projects

- 10": Ideal for table saws and circular saws for cutting metal applications

- 12": Suited for large miter saws and professional-grade cutting stations

Ensuring Arbor Hole Compatibility

The arbor hole - the center opening that mounts the blade to the saw - must match your saw's specifications exactly. Most 7-1/4" blades feature a 5/8" arbor hole, while larger blades may require different sizes. Using a blade with an incorrect arbor size can result in wobbling, uneven cuts, and dangerous operating conditions. Some blades include knockout rings to accommodate multiple arbor sizes, offering greater versatility across different saw models.

For example, the CMT 226.348.07 is a metal and stainless steel blade designed to handle tough materials while providing longevity due to its chrome plating that protects against corrosion and residue build-up.

Additionally, if you're looking for specialized cutting tools such as diamond dry hole saws, or dowel drills for through holes, Prime Source offers a variety of options tailored to specific needs.

Safety Considerations When Using Circular Saws

Safety is crucial when using a circular saw with a rotating blade. The high-speed spinning of the saw blades requires strict following of safety measures to avoid accidents and ensure the best performance.

Essential Safety Gear:

- Impact-resistant safety goggles to protect eyes from debris

- Hearing protection for noise reduction

- Heavy-duty work gloves for enhanced grip

- Dust mask to prevent inhalation of particles

- Steel-toed boots for foot protection

- Close-fitting clothing to avoid entanglement

Blade Maintenance Guidelines:

- Inspect the circular saw blade before each use

- Check for missing or damaged teeth

- Look for signs of warping or cracking

- Clean blade surfaces regularly to prevent buildup

- Replace blades showing signs of wear

A dull circular saw blade can be dangerous, causing kickback and uneven cuts. Regularly changing blades keeps cuts precise and reduces strain on the motor. When cutting metal with a circular saw, watch out for these warning signs that indicate it's time to replace the blade:

- Increased resistance during cuts

- Burning smell while operating

- Visible wear on blade teeth

- Rough or uneven cut surfaces

- Excessive noise during operation

Taking care of your blades isn't just about safety - it also affects how well your tools work and how long they last. By setting up a regular inspection routine, you can catch potential problems before they affect safety or performance.

Additional Considerations for Specialized Projects

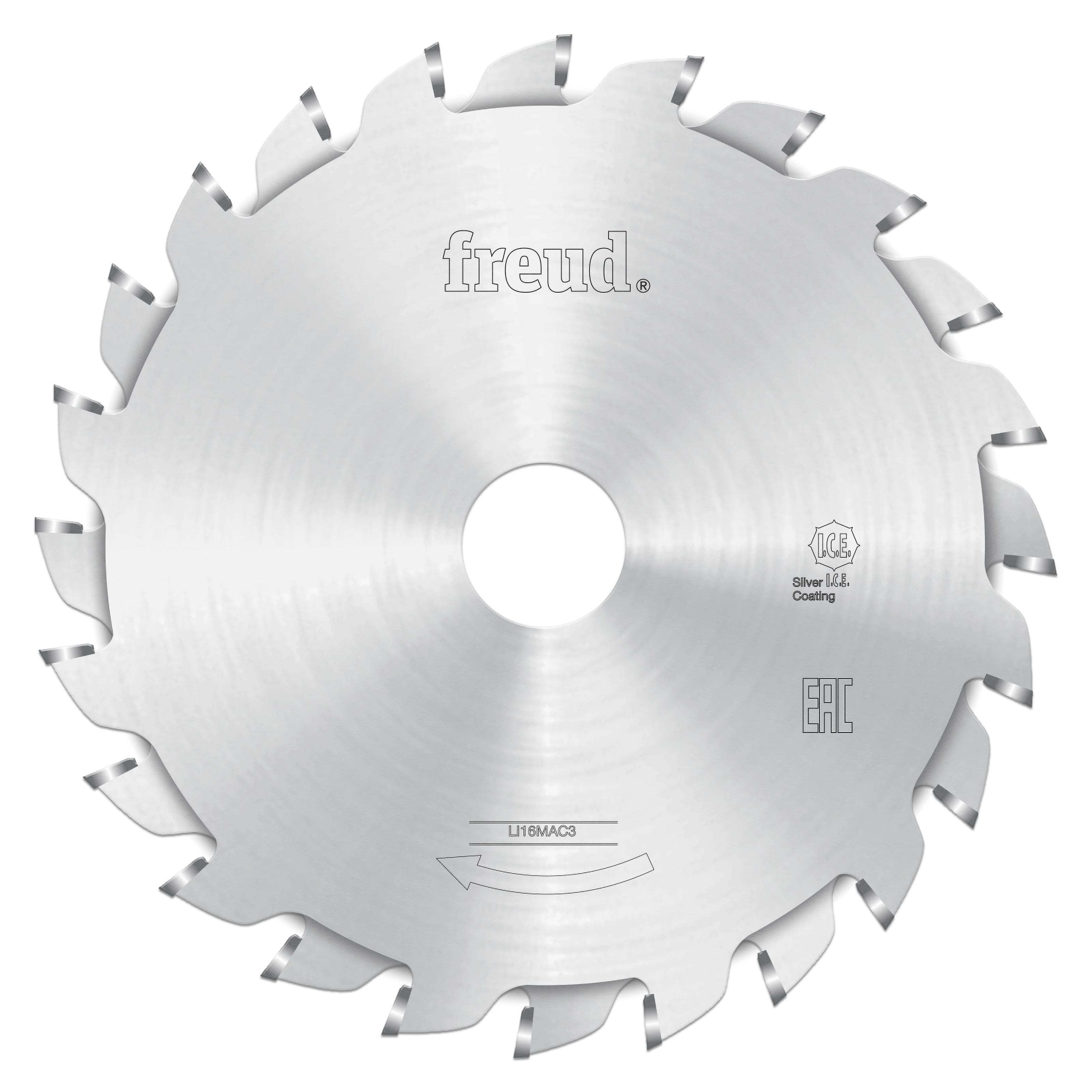

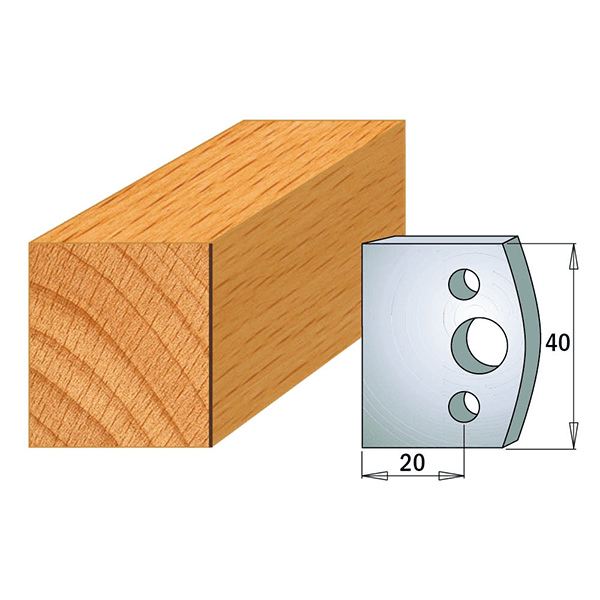

Specialized projects demand specific circular saw blades designed to meet unique cutting requirements. Fine-tooth finish blades excel in cabinetry and joinery work, delivering pristine cuts essential for professional-grade furniture pieces. These rotating saw blades feature up to 80 teeth per inch, creating glass-smooth edges that require minimal sanding.

Cabinetry and Joinery Requirements:

- 60-80 tooth blades for hardwood veneers

- Negative hook angles to prevent tear-out

- Triple-chip grind for clean cuts through melamine

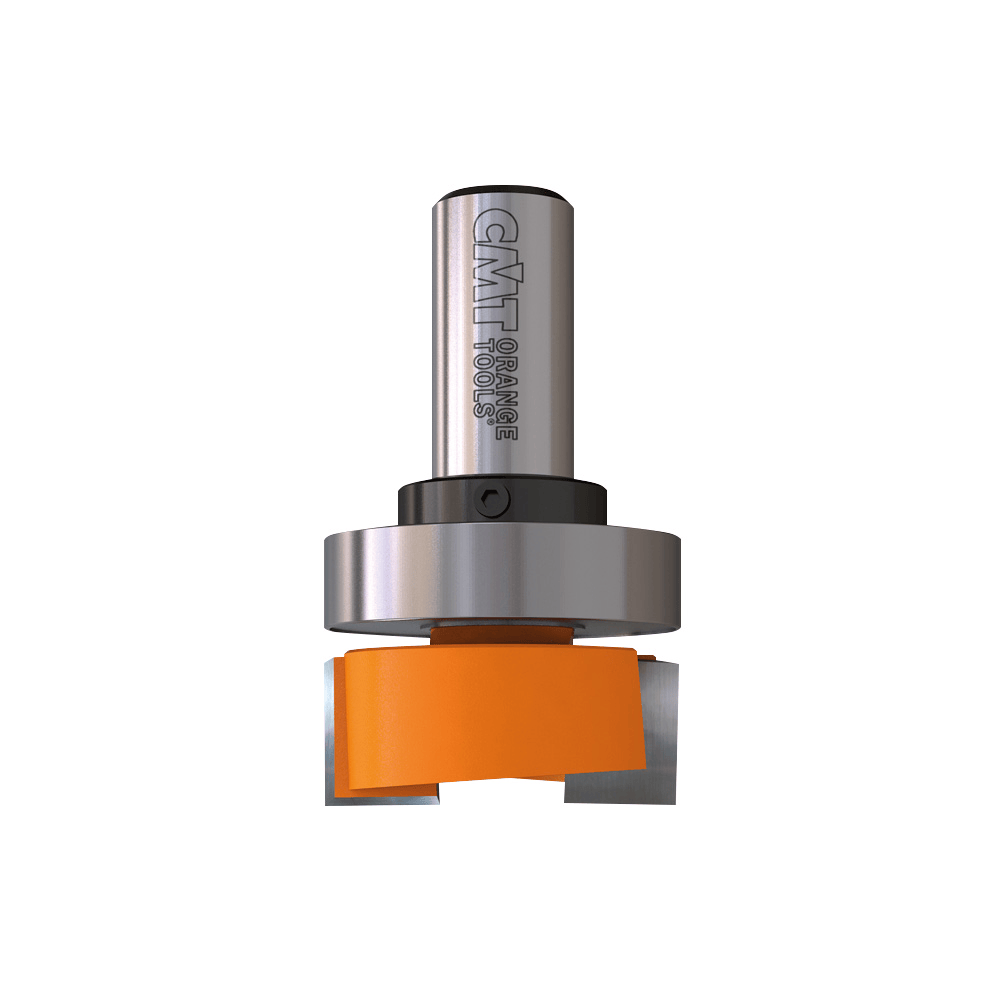

In addition to circular saw blades, specialized router cutters like the CMT 663.005.11 spoilboard surfacing router cutters with insert knives can be invaluable in cabinetry work. These cutters are made of super strength steel and come with multiple cutting edges for superior performance.

Demolition projects present different challenges, requiring robust circular saw blades built to handle mixed materials. Nail-cutting blades incorporate specialized carbide teeth designed to power through embedded nails without damage. These saw circular blade variants feature:

- Reinforced shoulder design

- Impact-resistant carbide teeth

- Thicker plate construction

The circular saw for cutting metal during demolition work needs particular attention to blade selection. Specialized demolition blades offer:

- Heat-resistant coating

- Aggressive tooth geometry

- Enhanced debris ejection channels

For optimal results in specialized applications, match the blade's specifications to your specific project requirements. High-precision cabinetry demands fine-tooth blades or specialized router bits like the CMT 851.501.11B bowl & tray bit, while demolition work requires durable, multi-purpose options capable of handling various materials and embedded fasteners.

Conclusion

Choosing the right circular saw blade is crucial for the success of your project. The right blade can turn difficult cuts into precise, professional results. At Prime Source, we offer a wide selection of circular saw blades to meet every specific need - whether you're working on intricate cabinetry or heavy-duty construction.

Our knowledgeable team is always available to help you find the perfect circular saw blade for your specific needs. We understand that different materials require different blades, and we're here to guide you through the selection process.

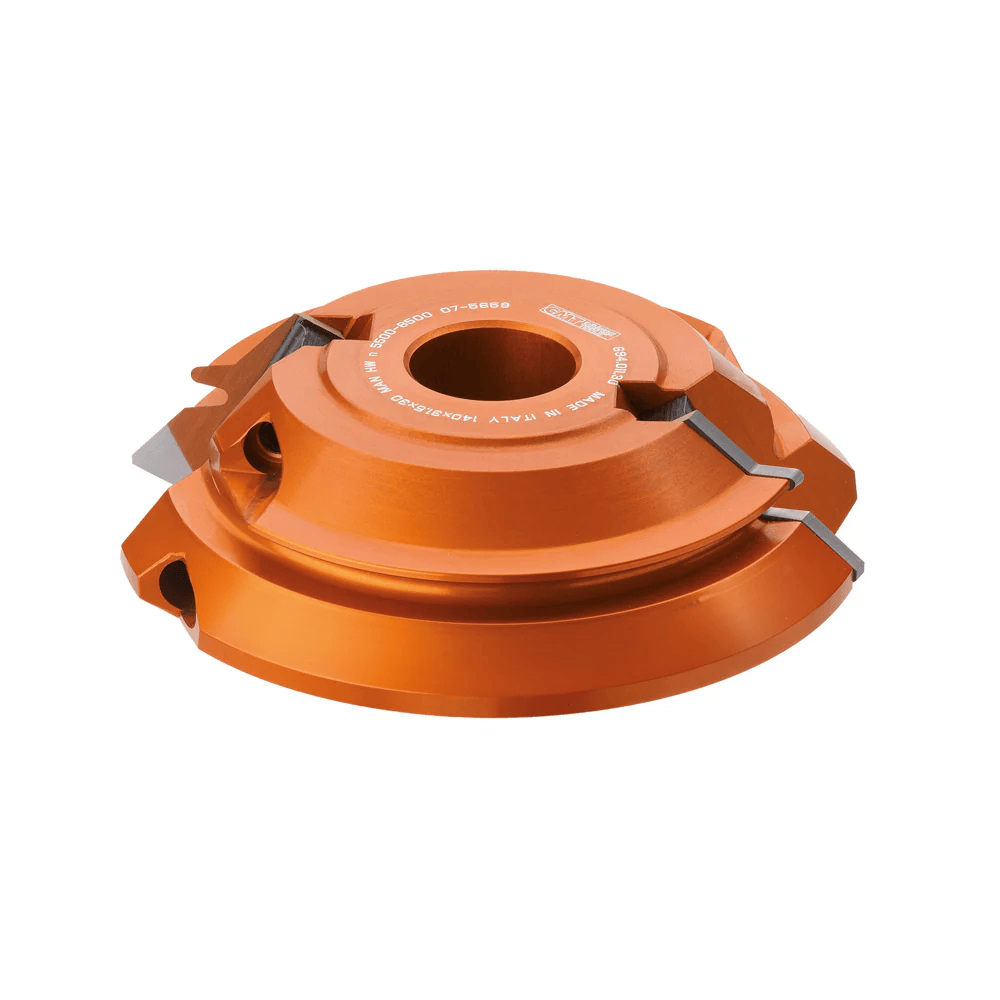

In addition to circular saw blades, we also carry a variety of specialized tools such as CMT 690.022 profile knives for insert shaper systems. These knives are ideal for achieving intricate designs in cabinetry work.

Make your next project a masterpiece - visit Prime Source today to explore our extensive range of cutting solutions.

FREQUENTLY ASKED QUESTIONS

Selecting the right circular saw blade is crucial for project efficiency. The correct blade enhances cutting performance, improves finish quality, and ensures safety during operations.

The main types of circular saw blades include carbide-tipped blades, high-speed steel blades, and diamond-tipped blades. Each type has specific applications: carbide-tipped blades are ideal for hardwoods, high-speed steel blades are budget-friendly for light tasks, and diamond-tipped blades excel in cutting concrete and stone.

TPI affects both cut quality and speed. Fewer teeth provide faster cuts but may result in rougher finishes, while more teeth yield smoother finishes but can slow down the cutting process. It's important to choose TPI based on the desired outcome of your project.

Key features to evaluate include tooth hook angle, expansion slots, coatings on saw blades, and compatibility with your saw's arbor hole size. These factors influence cut quality, prevent warping, reduce friction, and ensure proper fitting.

Always use appropriate safety gear during operations to protect yourself. Additionally, regularly replacing dull or damaged blades is essential to maintain optimal performance and ensure safe cutting conditions.

For cabinetry or joinery projects, fine-tooth finish blades are recommended for a smooth cut. For demolition work or cutting through nails, nail-cutting blades are appropriate tools that enhance efficiency in those tasks.