Essential Maintenance Tips to Extend the Life of Your Circular Saw Blades

Introduction

A well-maintained circular saw blade is the cornerstone of precision woodworking and metalworking. These essential tools face daily challenges that can impact their performance and lifespan. From dulling edges to misalignment issues, the rotating saw blade encounters various obstacles that can compromise its cutting efficiency.

Many users experience common problems with their saw circular blade, including:

- Reduced cutting precision

- Blade wobble

- Excessive noise during operation

- Burn marks on cut materials

- Premature wear and tear

At Prime Source, we understand the critical role that quality tools play in your projects. With over a decade of industry experience, we've witnessed how proper maintenance can transform a circular saw for cutting metal from an average tool into a precision instrument. Our commitment to providing superior tools goes hand-in-hand with educating our customers about proper maintenance practices.

This guide will explore essential maintenance techniques to help you maximize your blade's performance and longevity, ensuring clean cuts and professional results for years to come.

Why Blade Maintenance Matters

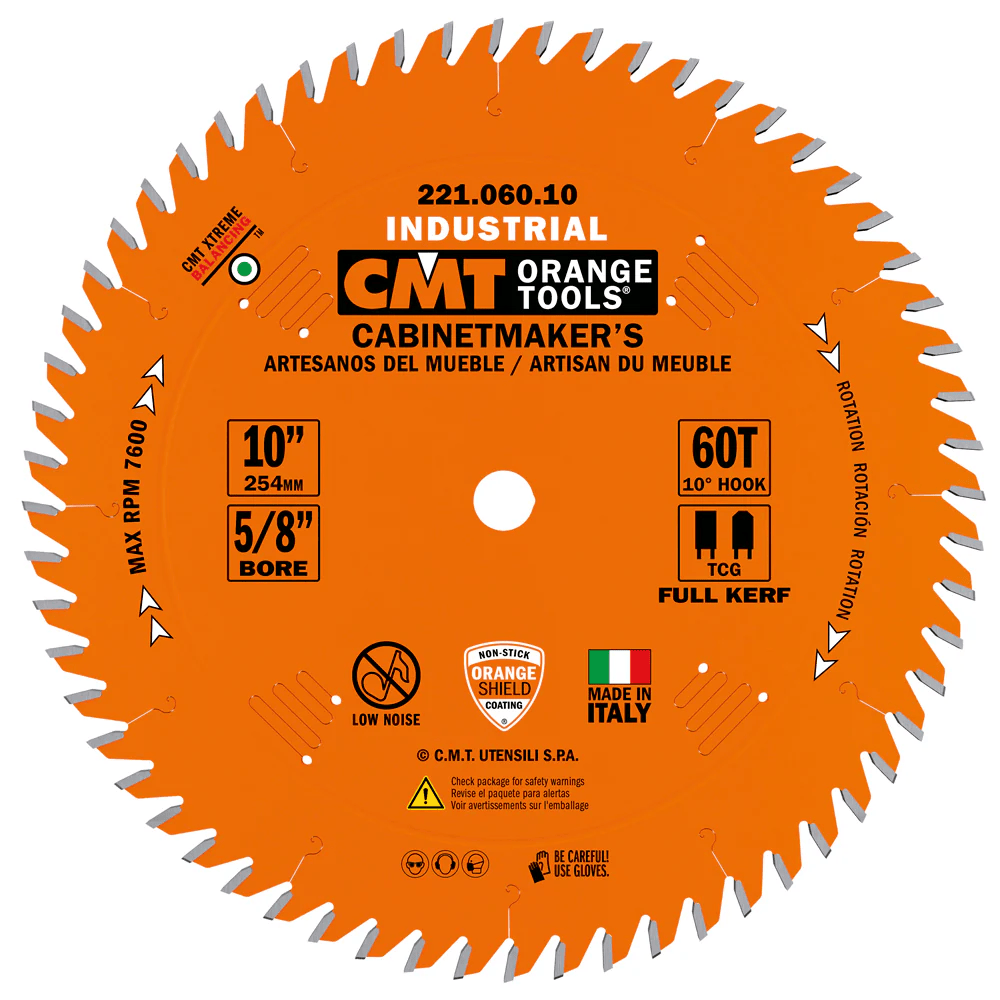

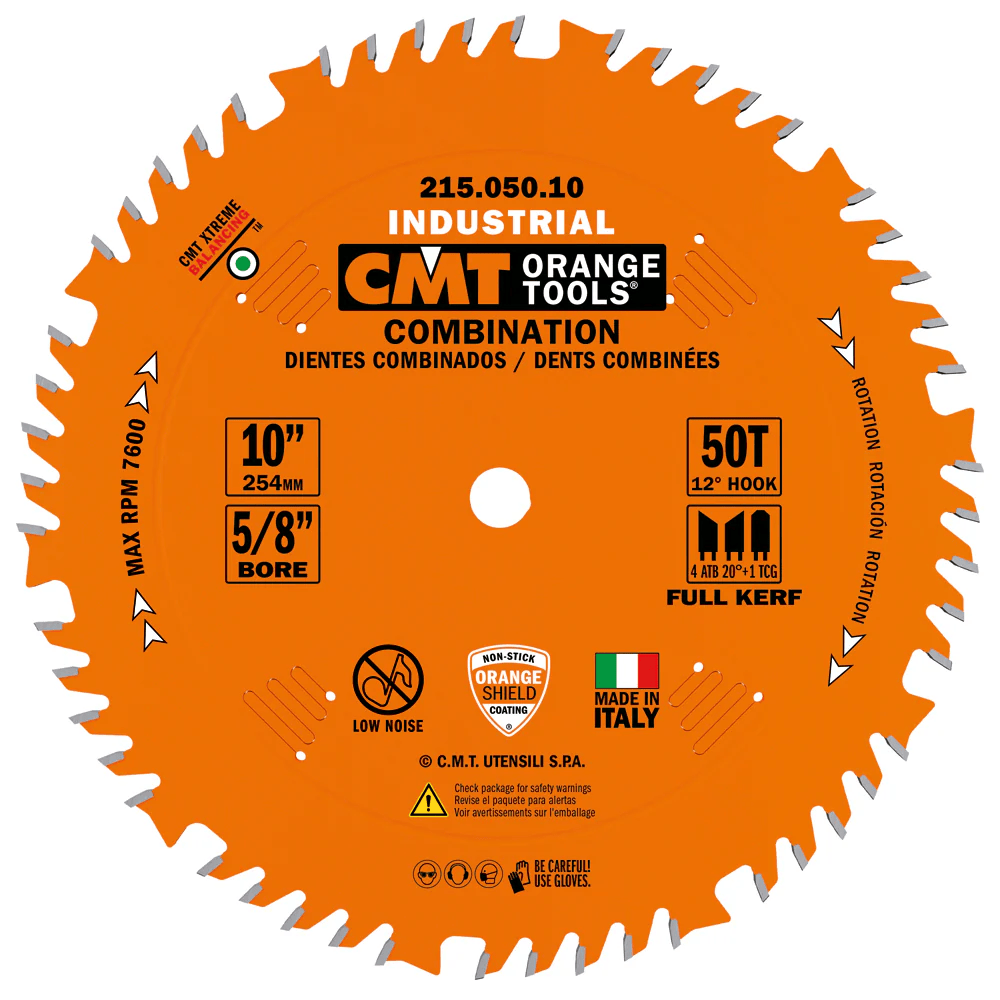

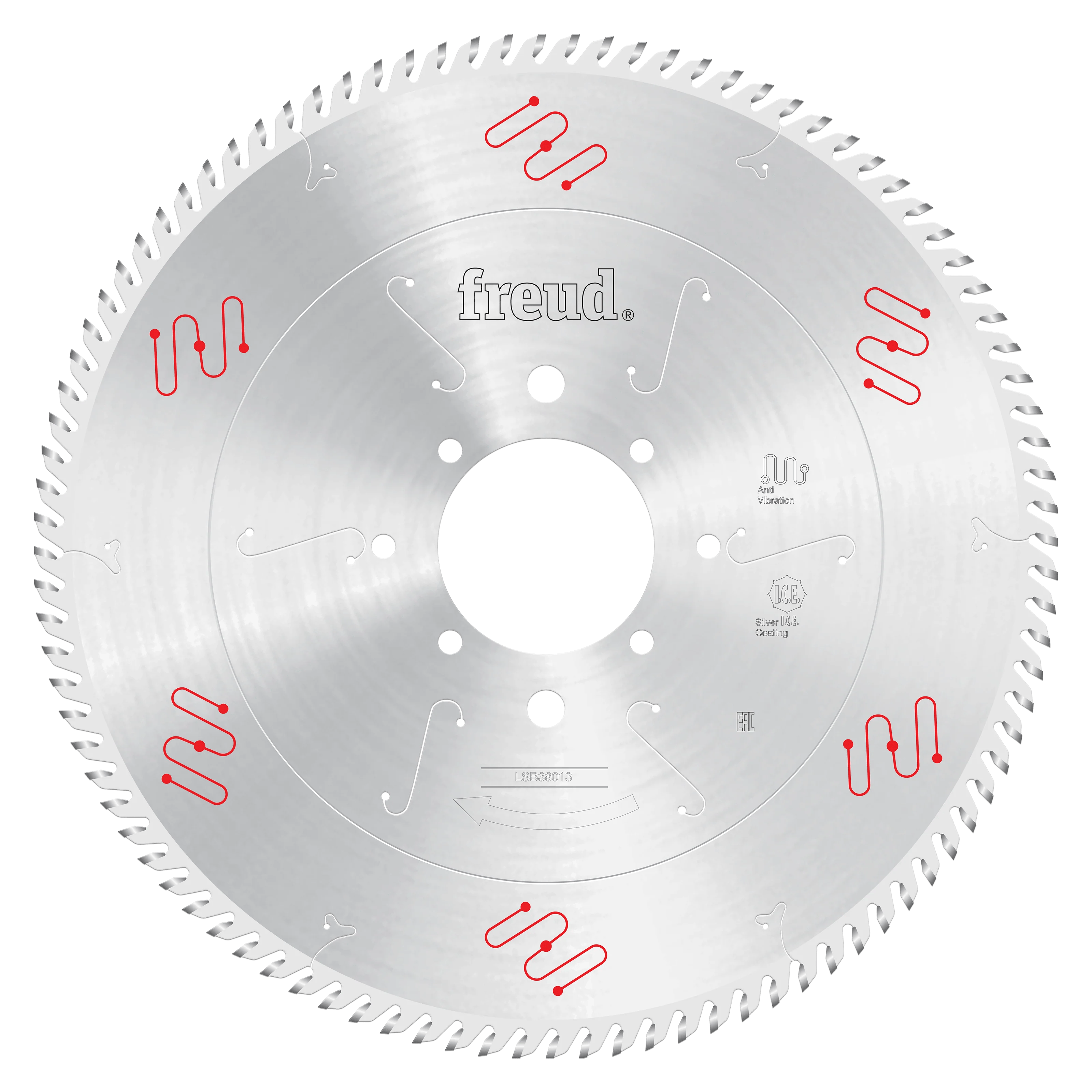

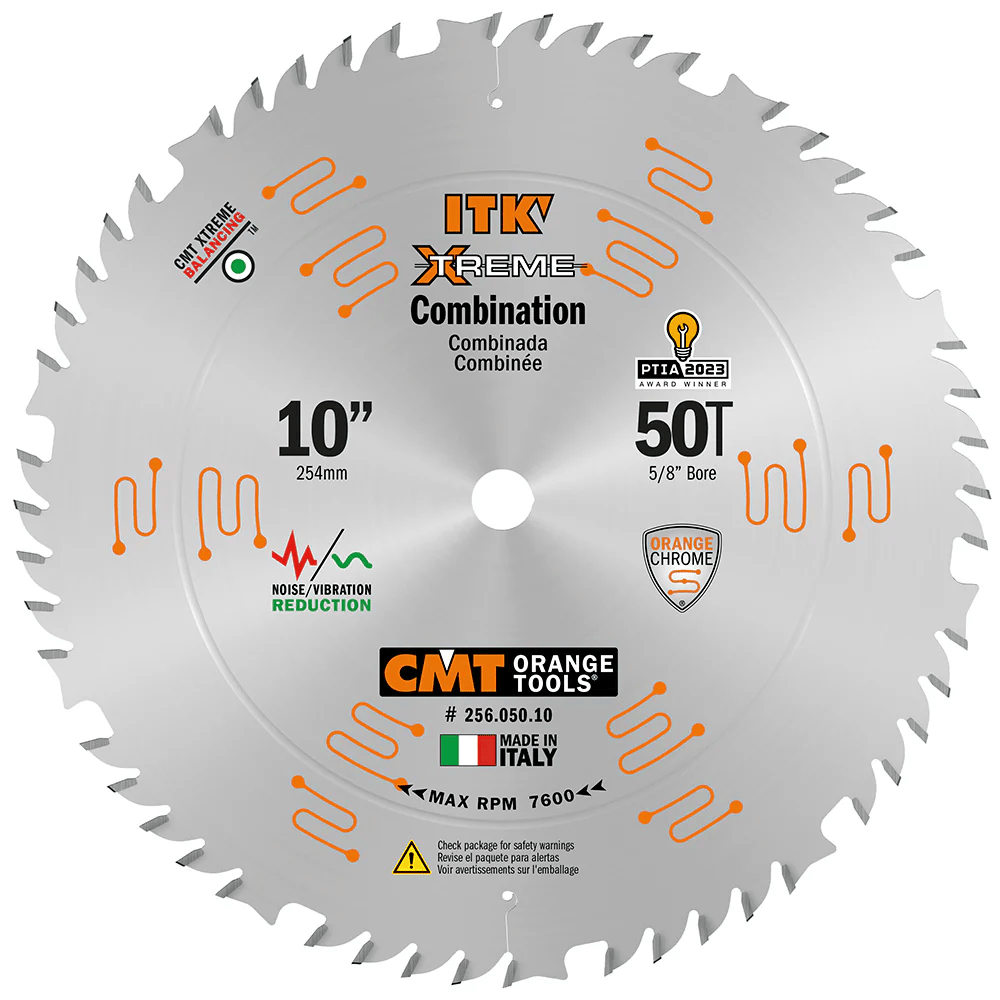

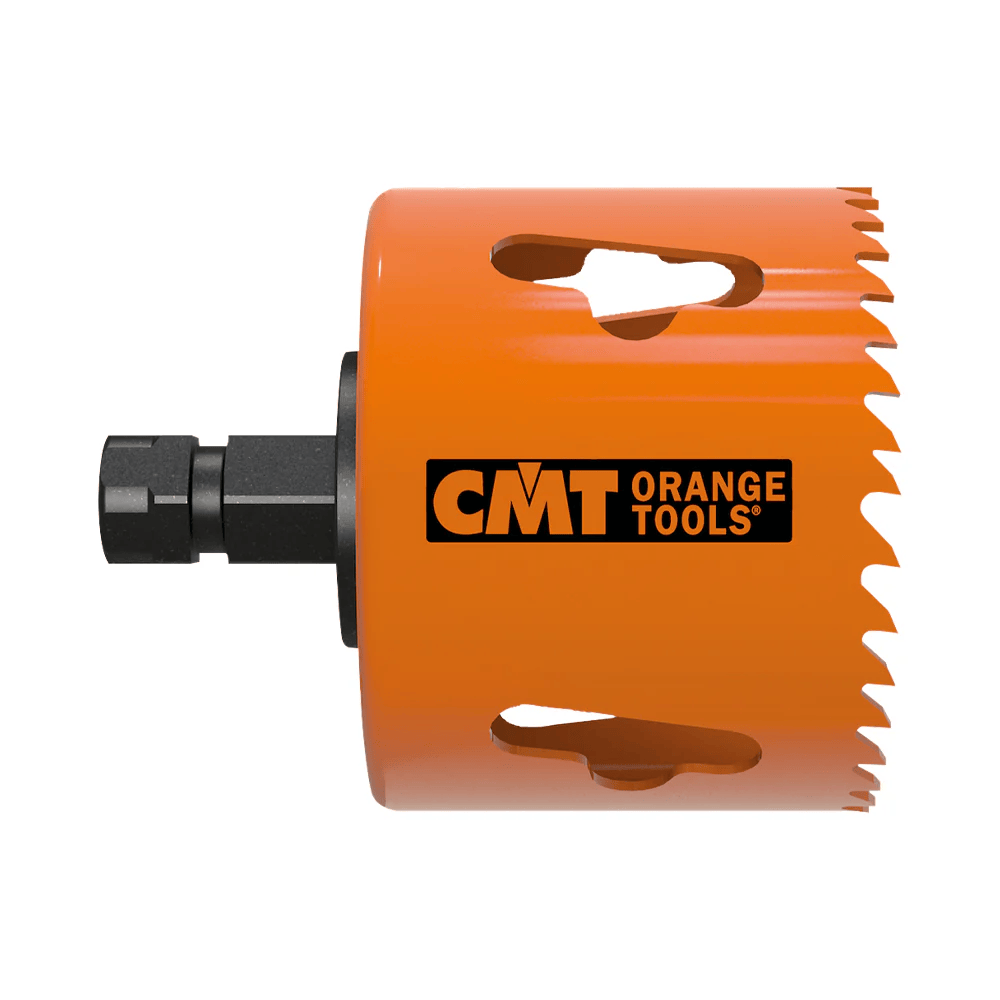

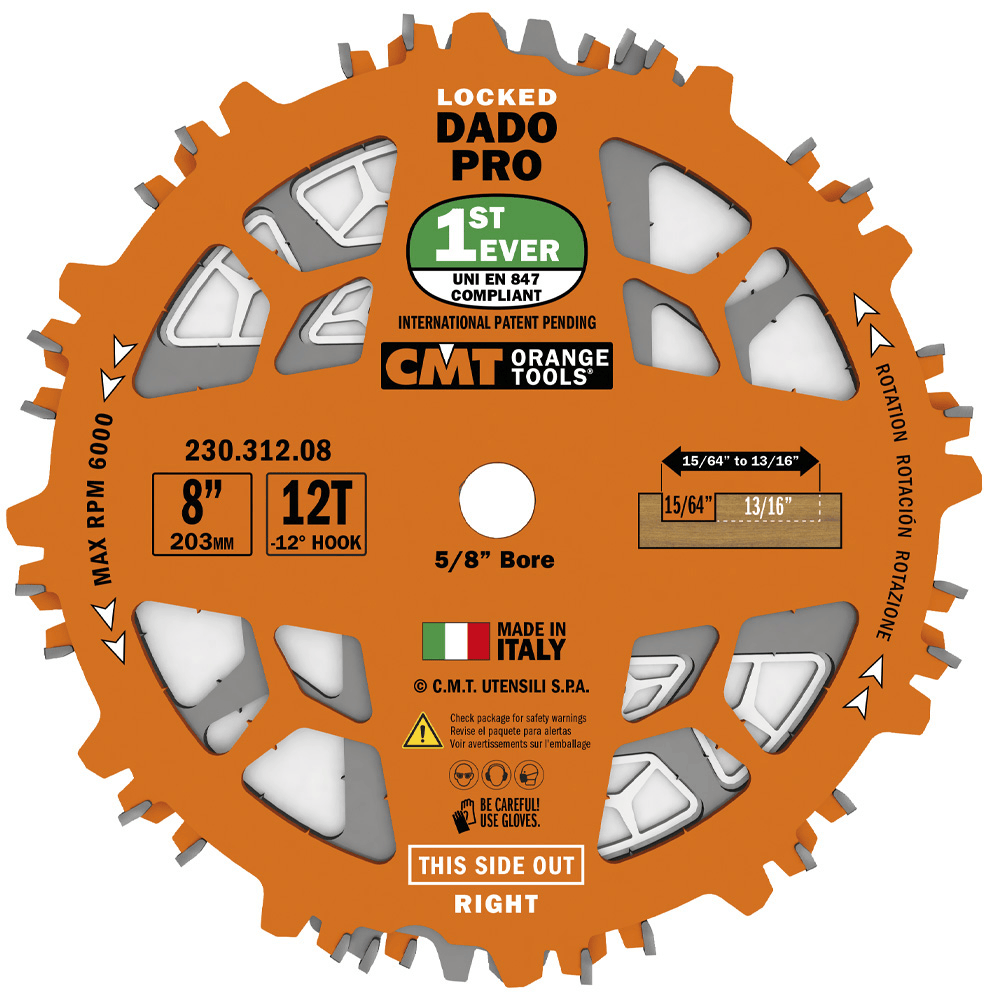

A well-maintained circular saw blade, like the CMT 285.680.12, delivers precise, clean cuts while reducing strain on your equipment. Regular maintenance directly impacts blade performance and extends the lifespan of your rotating saw blade by preventing premature wear and damage.

The Consequences of Neglected Blades

Neglected circular saw blades create rough, uneven cuts that can ruin expensive materials and compromise project quality. Dull or damaged blades force motors to work harder, leading to:

- Increased power consumption

- Excessive heat buildup

- Accelerated wear on equipment

- Higher risk of workplace accidents

- Poor quality finished products

How Proper Maintenance Saves Money

Proper maintenance of your circular saw for cutting metal saves money by:

- Reducing the frequency of blade replacements

- Minimizing material waste from poor cuts

- Decreasing equipment repair costs

- Maintaining optimal cutting efficiency

- Extending tool lifespan

The Importance of Professional Maintenance

A small investment in regular blade care prevents costly repairs and replacements while ensuring consistent, professional results. Professional maintenance practices protect both your equipment and reputation, making it an essential aspect of tool ownership.

For instance, using high-quality blades like the CMT 284.720.12 for thick non-ferrous metals or melamine can significantly improve cutting efficiency and prolong tool lifespan.

Investing in proper maintenance and high-quality tools not only enhances performance but also safeguards your financial resources in the long run.

Essential Maintenance Tips for Circular Saw Blades

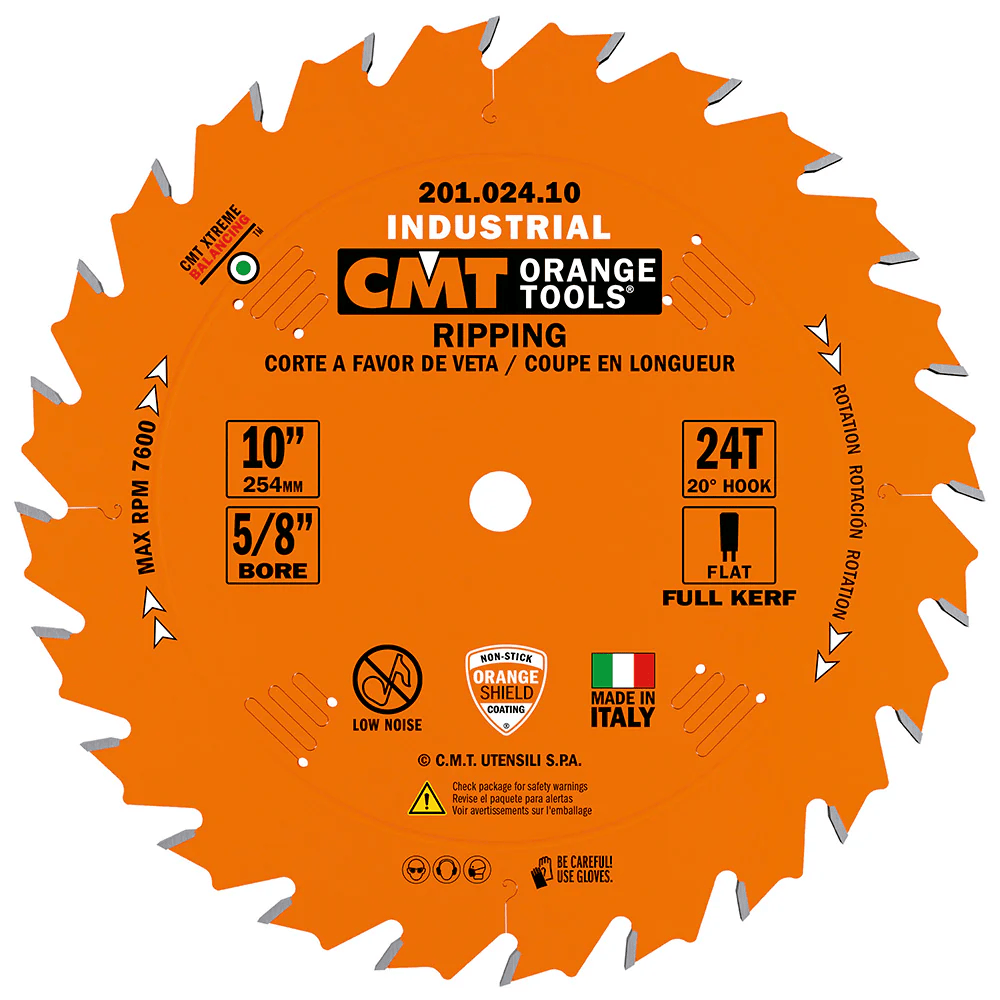

Proper maintenance of your rotating saw blade requires a systematic approach to ensure optimal performance and longevity. Here are nine critical maintenance practices that will help preserve your investment:

1. Keep the Cutting Area Clean

A clean workspace directly impacts the performance of your circular saw blades. Accumulated debris can cause:

- Uneven cutting patterns

- Premature blade wear

- Reduced cutting accuracy

- Potential safety hazards

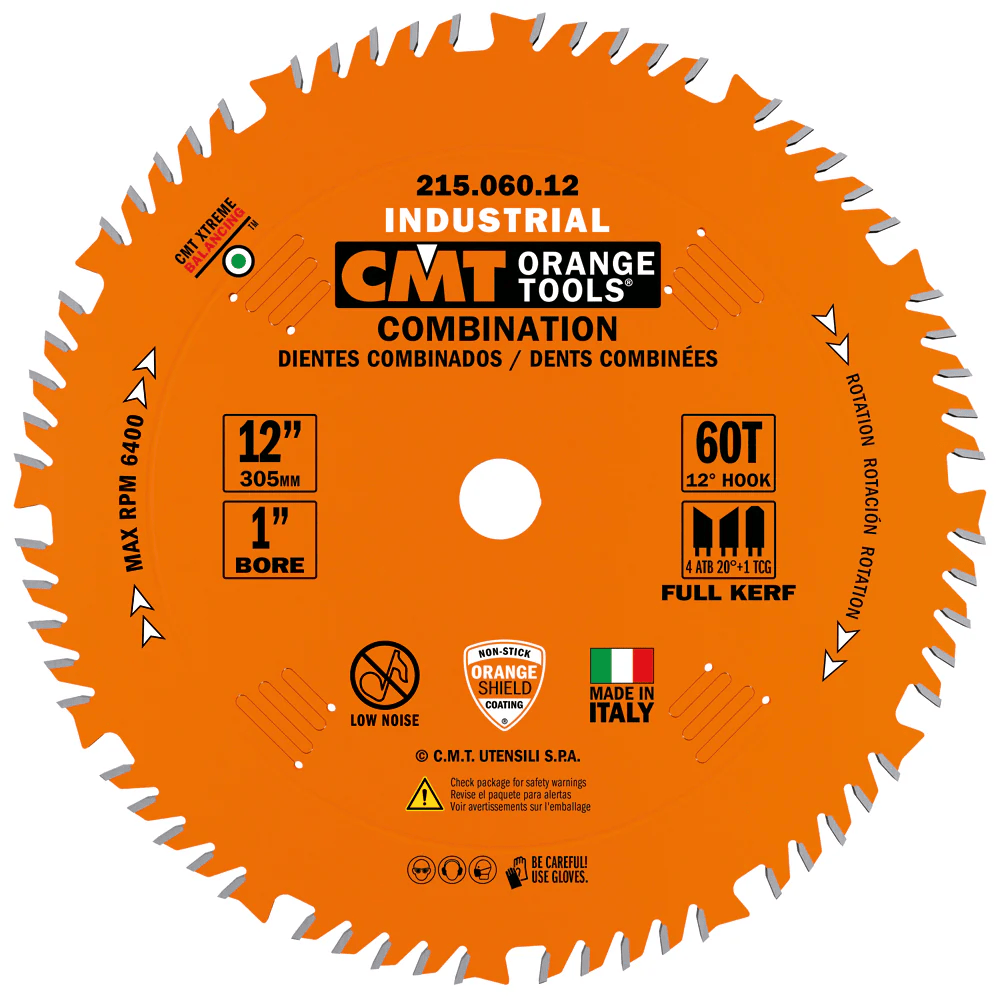

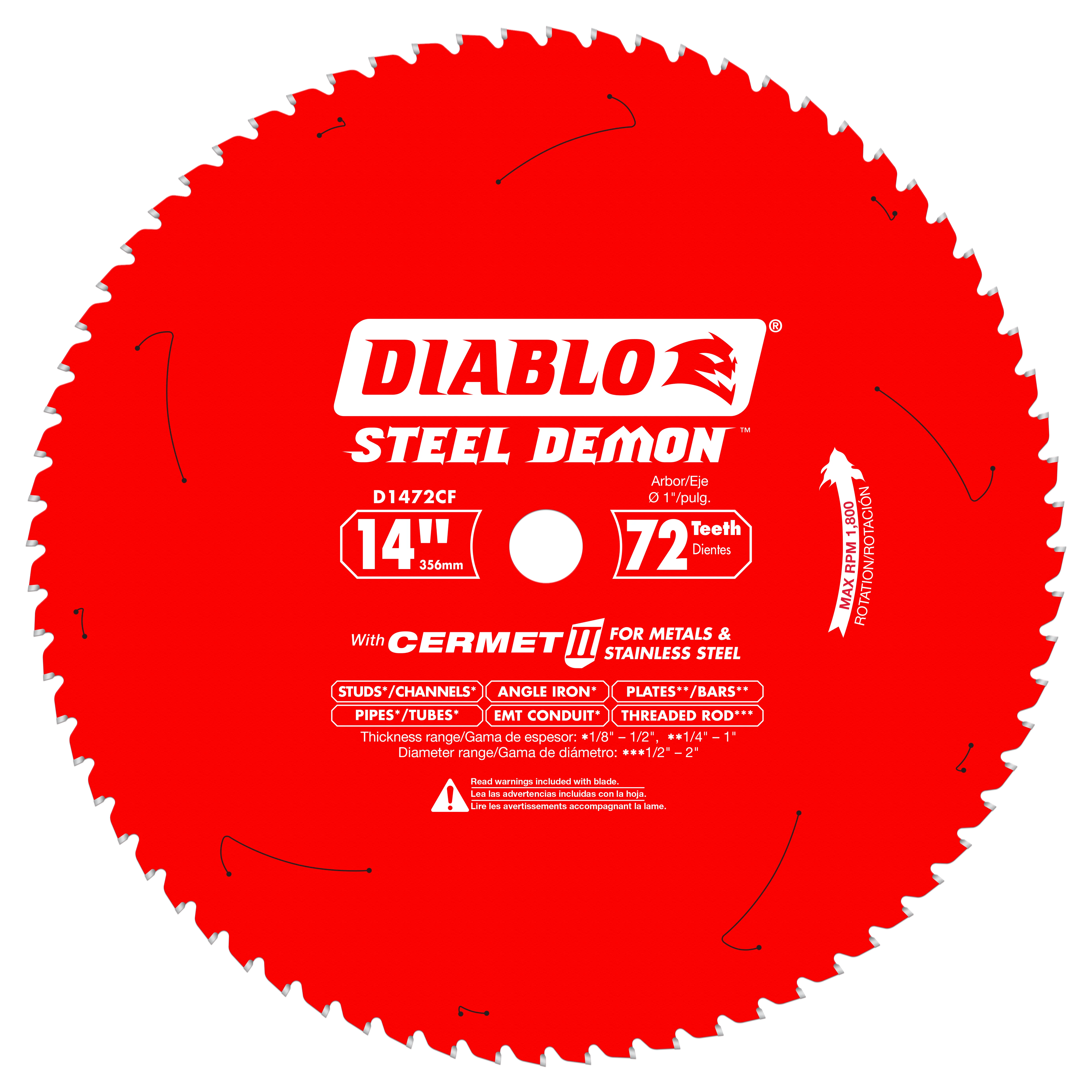

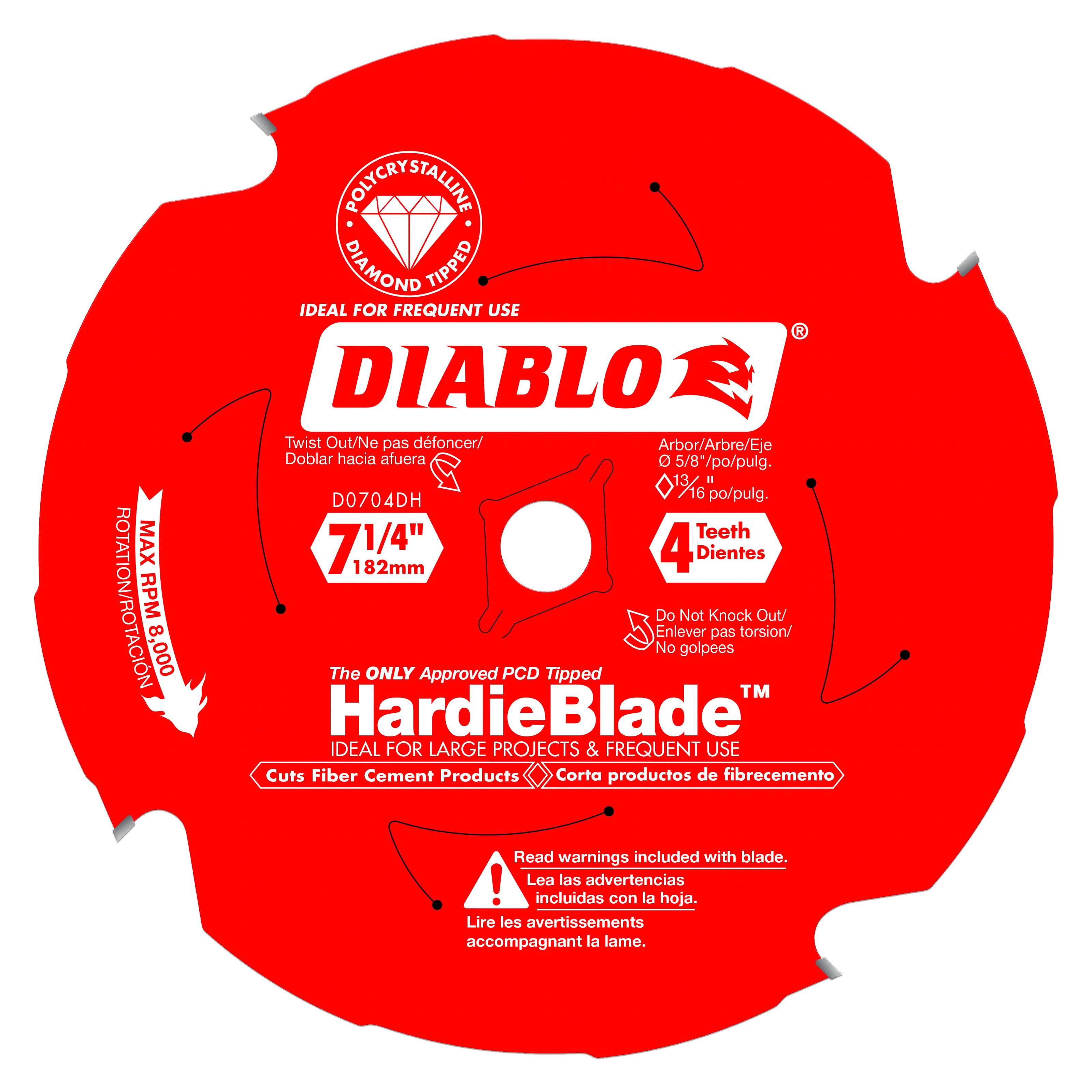

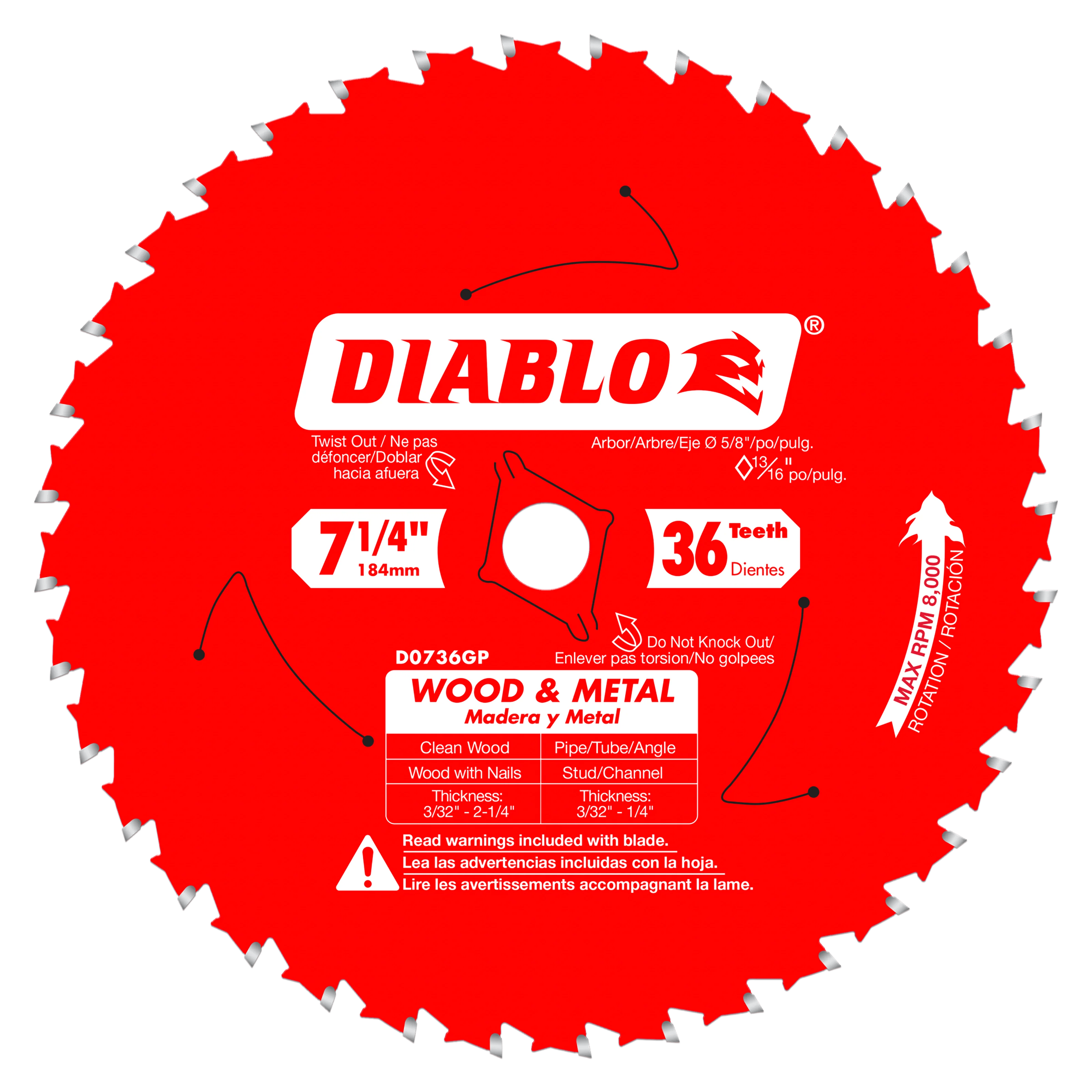

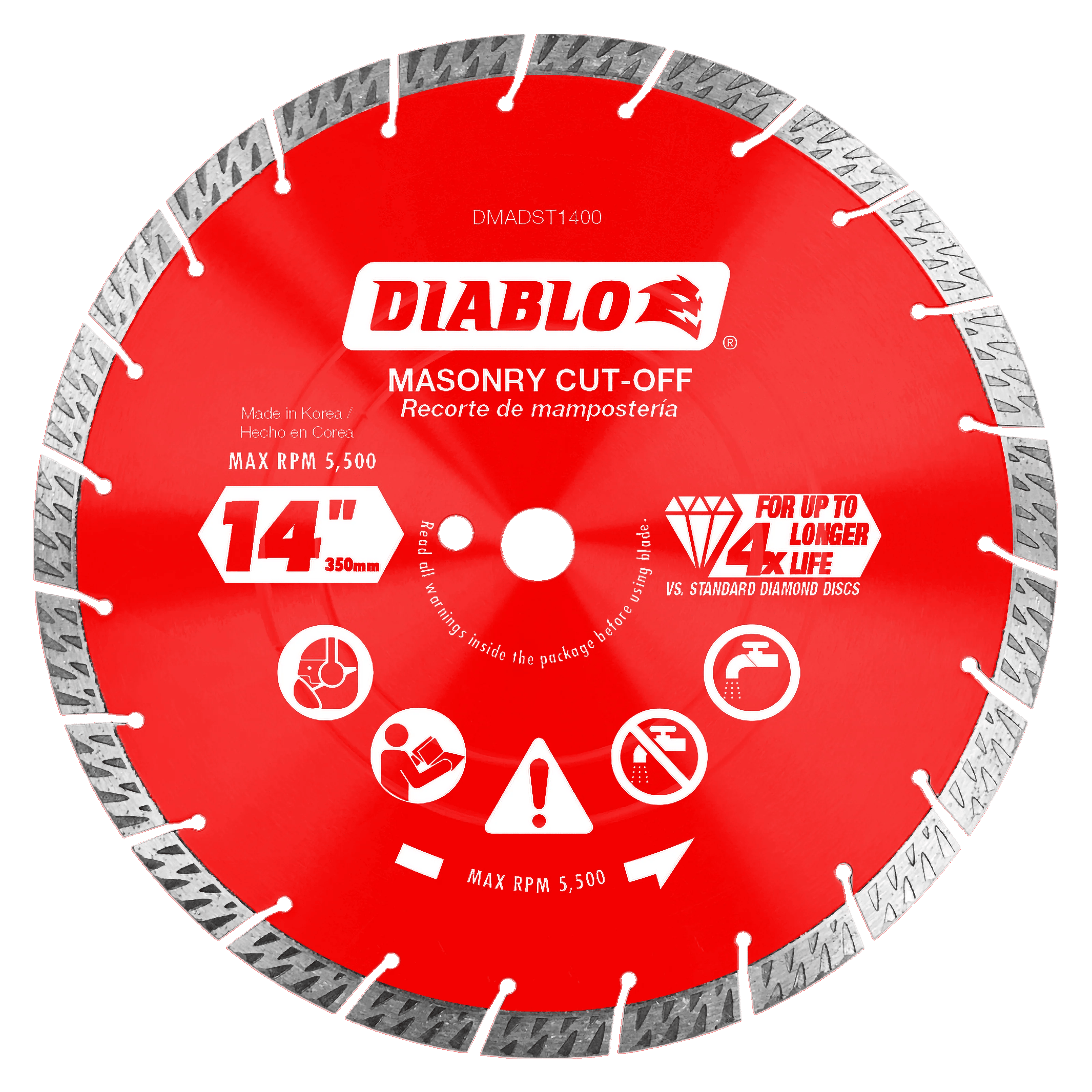

Use a chip brush to remove sawdust and debris from both the blade and cutting area. For metalworking applications, a circular saw for cutting metal like the Diablo D1472CF requires particular attention to metal chips that can become embedded in the cutting zone.

2. Check Fluid Levels

- Monitor coolant levels daily

- Check gearbox oil monthly

- Replace fluids according to manufacturer specifications

- Clean fluid reservoirs during replacement

Low fluid levels can lead to excessive heat buildup, causing premature wear on your saw circular blade.

3. Proper Blade Alignment

Blade alignment affects both cut quality and safety:

- Check blade-to-fence alignment

- Verify blade-to-table perpendicularity

- Adjust guide bearings as needed

- Test alignment with scrap material before production cuts

Misaligned blades create unnecessary stress on the cutting edge, reducing blade life and potentially causing dangerous kickback.

4. Regular Operation Checks

Implement these daily inspection points:

- Blade tension

- Bearing condition

- Drive belt integrity

- Mounting bolt tightness

- Arbor condition

- Guard functionality

5. Routine Cleaning and Sharpening

Maintain blade sharpness through regular cleaning and professional sharpening:

- Remove pitch buildup using specialized cleaners

- Clean between teeth using a brass brush

- Schedule professional sharpening every 12-15 hours of heavy use

- Look for signs of dulling: increased noise, slower cutting, rough finish

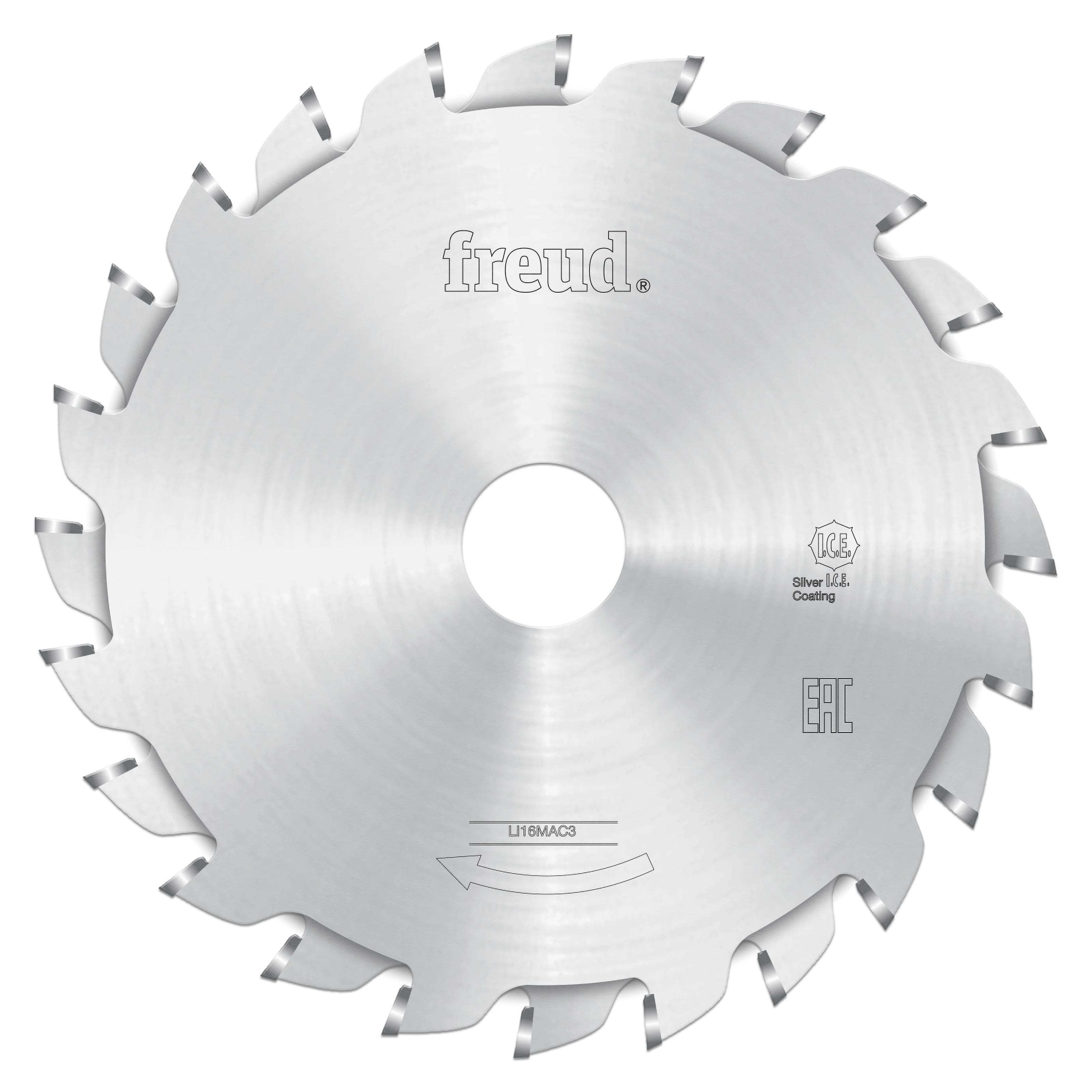

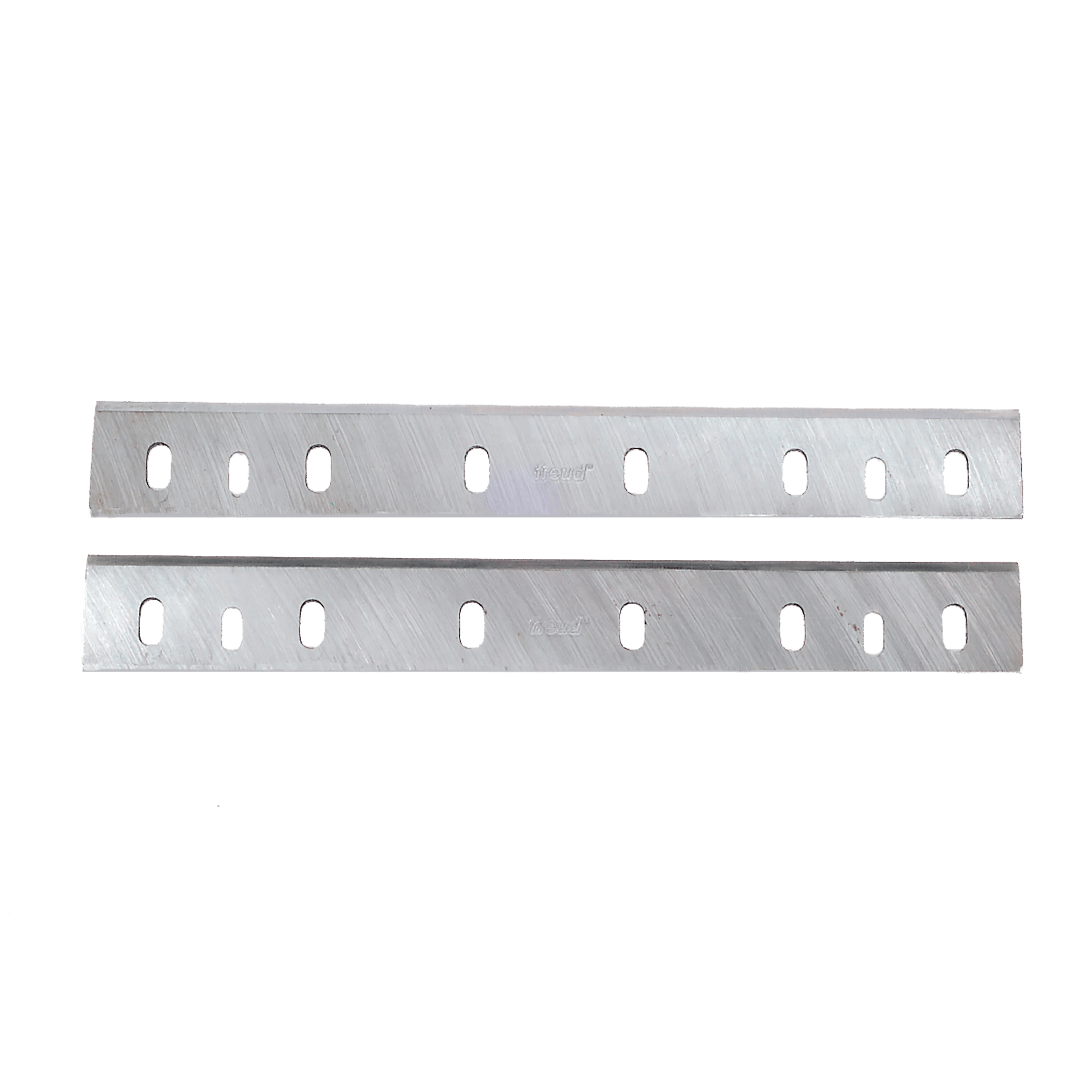

Consider using high-quality blades such as the Freud Lu90m10 for non-ferrous metals or composites, which require specific care.

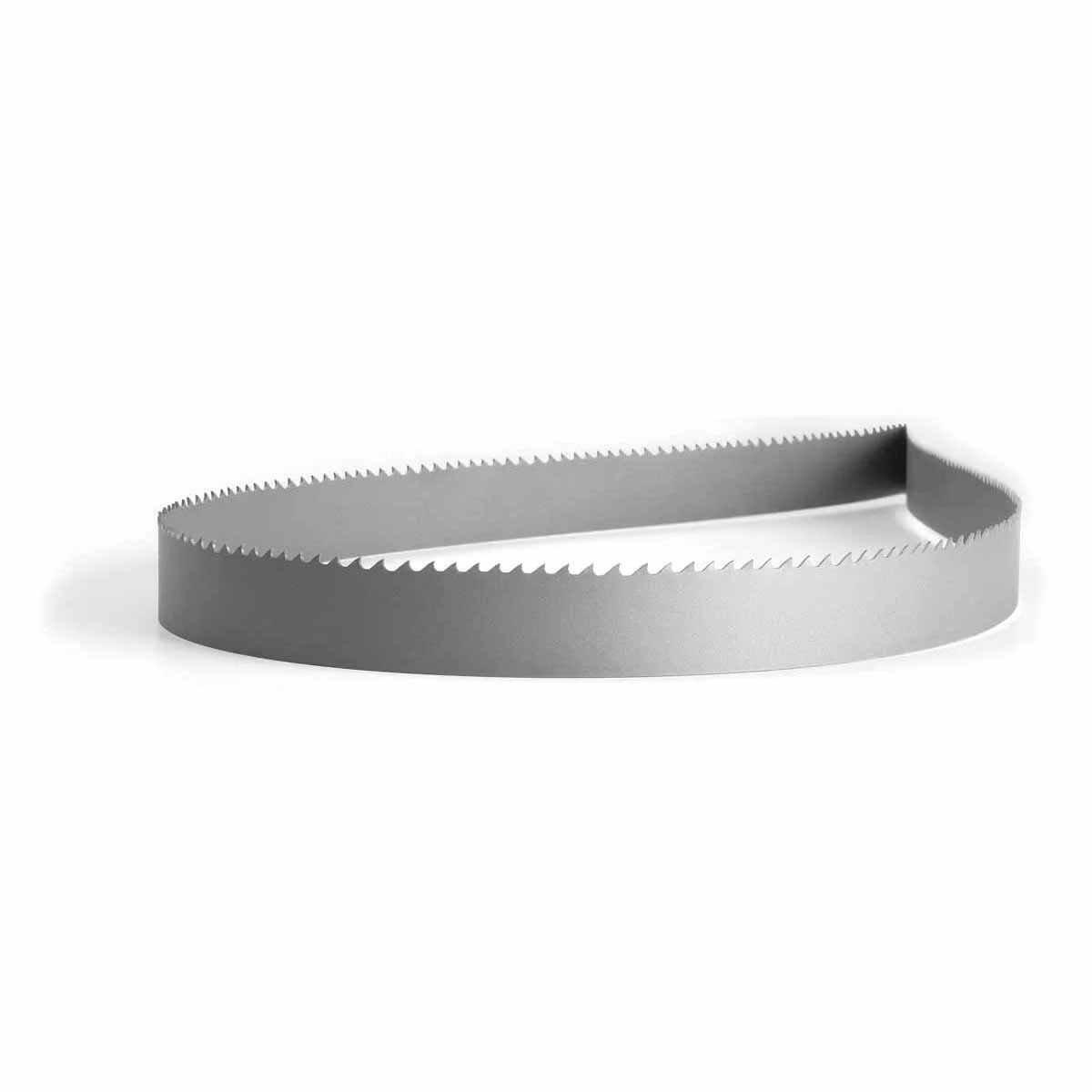

6. Proper Storage

Protect your investment with proper storage practices:

- Store blades flat to prevent warping

- Use individual blade covers

- Maintain a dry storage environment

- Keep blades separated to prevent tooth damage

- Apply light coating of rust preventative for long-term storage

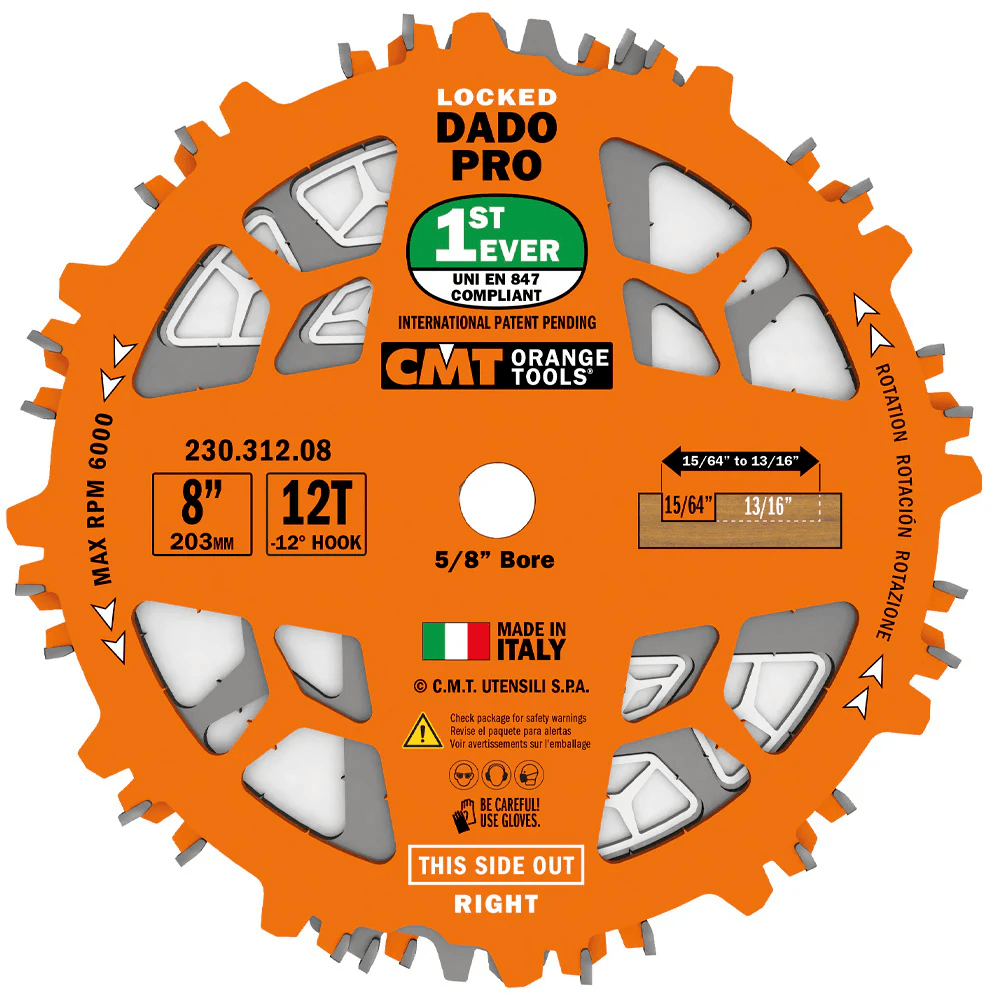

7. Correct Installation

Follow these installation steps:

- Clean mounting surfaces thoroughly

- Check arbor and flanges for damage

- Verify rotation direction arrows

- Tighten mounting bolt to specified torque

- Test run before cutting

8. Break-in New Blades

Proper break-in procedures extend blade life:

- Start with light cuts

- Gradually increase cutting depth

- Maintain steady feed rates

- Allow cooling between initial cuts

- Monitor blade temperature

Sharpening Your Circular Saw Blades for Optimal Performance

Keeping your circular saw blades sharp is crucial for maintaining cutting precision, reducing strain on your equipment, and prolonging blade life. A dull blade not only delivers poor-quality cuts but also increases the risk of overheating and excessive motor wear.

Signs That Your Blade Needs Sharpening

Regularly inspect your circular saw blade for these signs of dullness:

- Increased cutting resistance

- Rough, splintered, or burnt edges on materials

- Excessive noise or vibrations during operation

- Slower cutting speed than usual

- Increased motor strain and power consumption

How to Properly Sharpen Circular Saw Blades

1. Remove the Blade Safely

- Disconnect the power supply to your saw.

- Use a wrench to loosen the arbor bolt and carefully remove the blade.

2. Clean the Blade Before Sharpening

- Remove built-up pitch, resin, and debris using a blade cleaner or a diluted ammonia solution.

- Dry the blade thoroughly before sharpening.

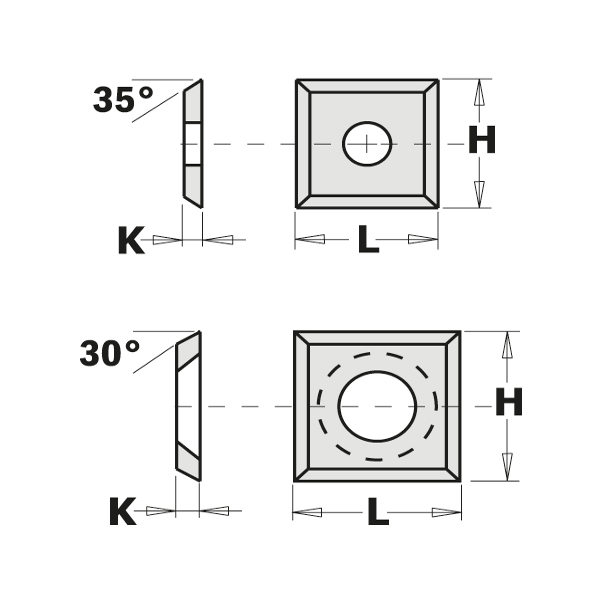

3. Choose the Right Sharpening Method

- Manual Sharpening: Use a diamond file to sharpen each tooth, following the factory bevel angle.

- Sharpening Jig: A dedicated sharpening jig ensures even and precise results.

- Professional Sharpening Service: For carbide-tipped blades, professional sharpening services can restore cutting precision without damaging the blade.

4. Maintain Proper Tooth Angle and Bevel

- Follow the original tooth geometry to maintain consistent cutting performance.

- Ensure equal pressure on all teeth to prevent imbalances that can cause wobbling.

5. Reinstall and Test the Blade

- Mount the blade back onto your saw, ensuring proper alignment.

- Perform a few test cuts on scrap material to verify sharpness and precision.

How Often Should You Sharpen Your Circular Saw Blade?

- Frequent use: Every 12-15 hours of heavy cutting

- Occasional use: Every few months, depending on wear

- When cutting tough materials: More frequent sharpening may be required for dense hardwoods, metal, or composites

Extending Blade Sharpness

To maintain sharpness for longer, consider:

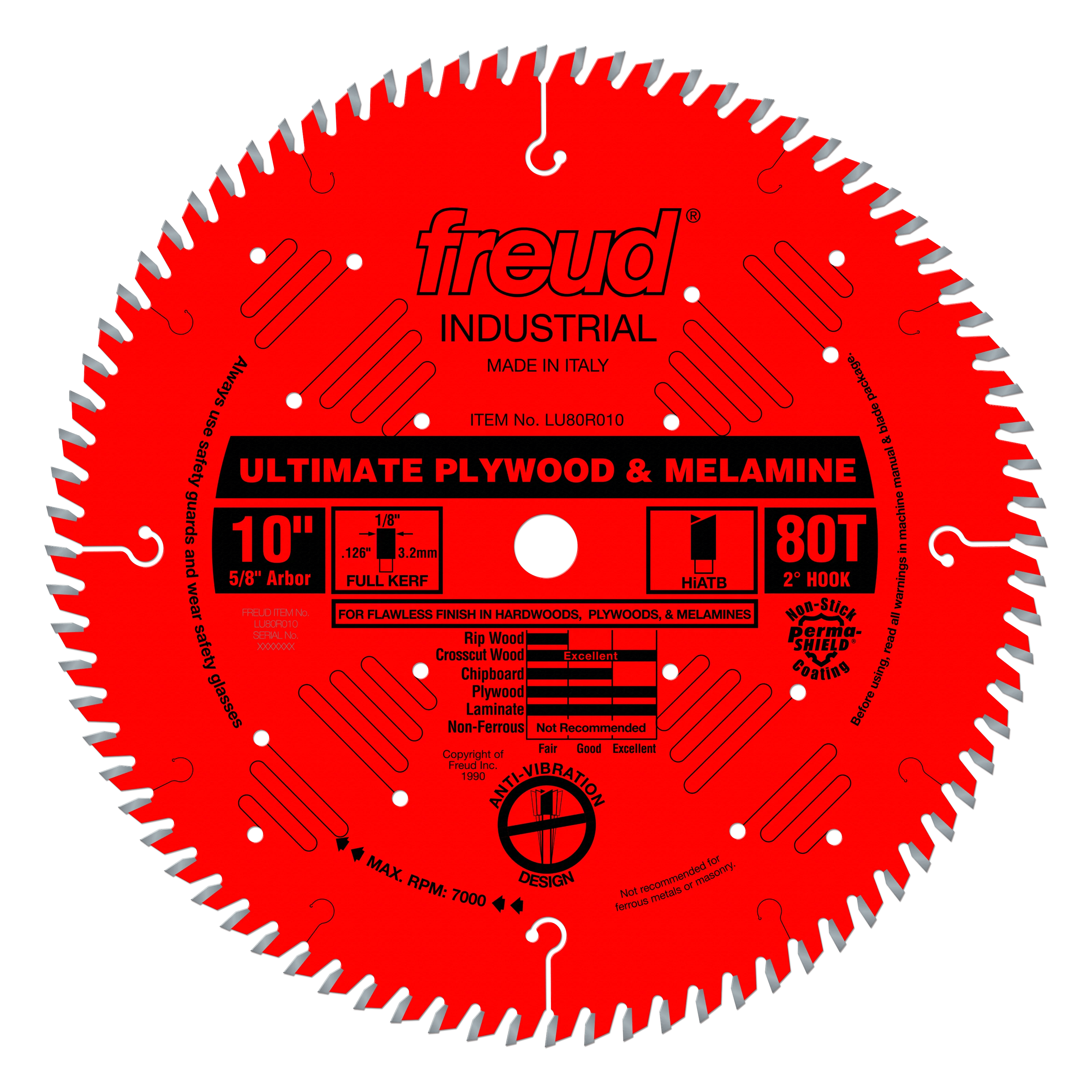

- Using high-quality blades like the CMT 285.680.12 for precision cuts

- Avoiding excessive feed pressure that can dull teeth faster

- Regularly cleaning the blade to prevent buildup

- Using a dedicated blade lubricant to minimize friction

By keeping your circular saw blades sharp, you'll achieve cleaner cuts, reduce tool wear, and enhance your overall woodworking or metalworking efficiency.

Conclusion

By following these essential maintenance tips, you can turn your circular saw blades from disposable tools into long-term investments. Each practice, whether it's proper cleaning or using the right speed settings, plays a crucial role in maximizing blade performance and lifespan. These strategies not only protect your tools but also save you money while ensuring precise cuts every time.

At Prime Source, we believe in the quality of our products. That's why we support every rotating saw blade we sell. But our commitment goes beyond just selling top-notch circular saw blades for cutting metal - we also want to empower you with the knowledge to maintain these tools effectively.

When you take care of your saw circular blades using these maintenance guidelines, you'll unlock their full potential and achieve professional-grade results in all your projects.

Remember: A well-maintained blade isn't just about making it last longer - it's about improving your craftsmanship, ensuring safety, and increasing efficiency with every cut.

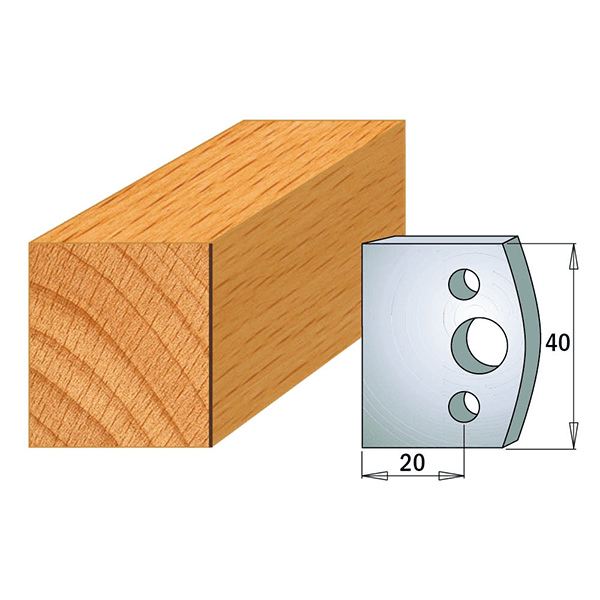

To further enhance your cutting experience, consider our range of specialized tools such as the CMT 690.010 profile knives or the CMT 310.080.12 dowel drill, which are designed for precision and durability. We also offer CMT 690.556 profile knives and CMT 807.128.11 flush trim bits that can greatly enhance your woodworking projects.

FREQUENTLY ASKED QUESTIONS

Maintaining circular saw blades is crucial for enhancing cutting efficiency, extending the tool's lifespan, and ensuring quality project outcomes. Neglected blades can lead to poor performance and increased costs due to frequent replacements.

Key maintenance tips include keeping the cutting area clean, checking fluid levels, ensuring proper blade alignment, performing regular operation checks, routine cleaning and sharpening, proper storage practices, correct installation of blades, properly breaking in new blades, and maintaining optimal cutting speeds and feeds.

To keep your circular saw blades clean, use a chip brush to remove debris and built-up pitch or resin. Regular cleaning is essential for maintaining blade performance and should be done after each use or when significant buildup occurs.

If your blade is misaligned, it can negatively impact performance. Ensure correct alignment before use by adjusting the guides and checking that the blade sits squarely in the machine setup. Regular checks can help avoid misalignment issues.

Blades should be sharpened based on usage; typically every few cuts or when you notice a decline in cutting efficiency. Regular sharpening helps maintain optimal performance and prolongs the life of your blades.

Best practices for storing saw blades include keeping them in protective covers to prevent rust and damage, storing them in a dry environment, and avoiding stacking them directly on top of one another to prevent warping or dulling.